The It can be a big task to transition from one-off projects to production using a CNC router. The associated costs and space needed alone may seem monumental at first glance. Some important things to consider are- Capacity and throughput: Make sure the CNC router can handle the increased workload, which may require upgrading to […]

Recently, our team had the pleasure of working on a project milling walnut into beautiful ring boxes. This project was a great opportunity for us to showcase the capabilities of our CNC routers and the skills of our team as we worked with a customer on developing a process for high production of walnut boxes. […]

A 3-axis CNC router can be an amazing tool for taking your woodworking business to the next level. It is equipped with a cutting tool that is mounted on a moveable arm, which is controlled by a computer to move in three different directions: the X-axis, the Y-axis, and the Z-axis. This allows the machine […]

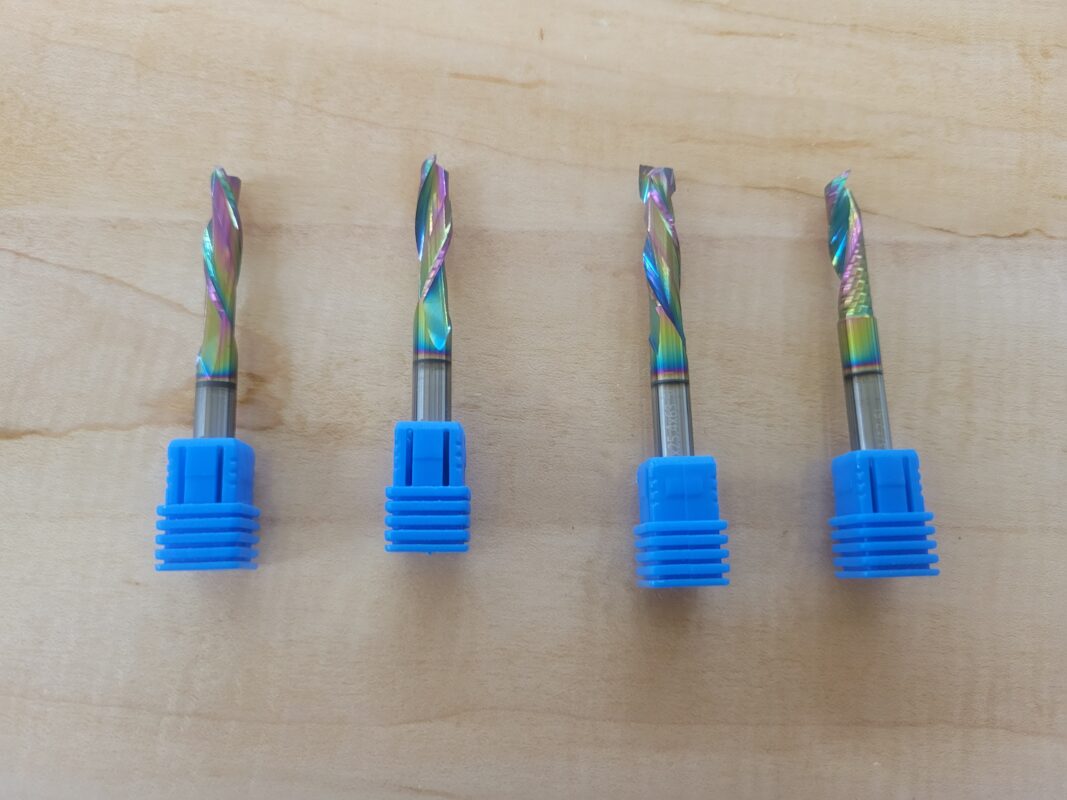

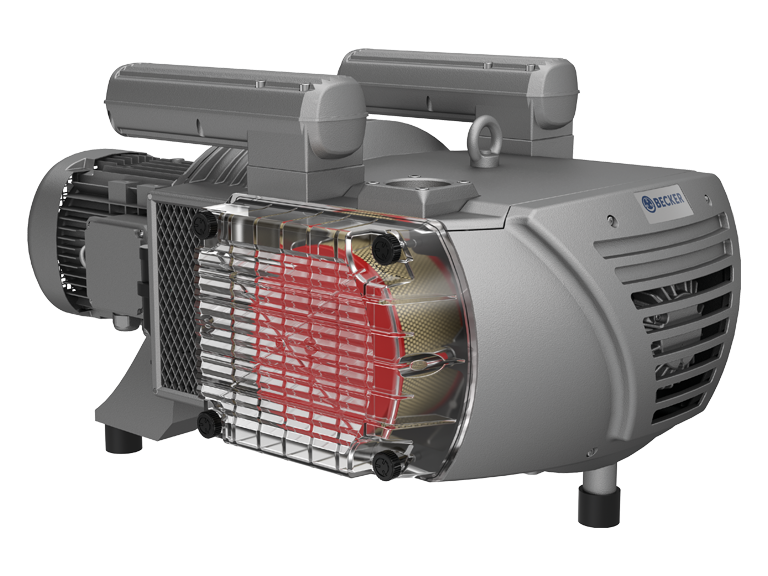

Using a vacuum pump with a CNC router can be an effective way to hold parts down during machining operations. The vacuum is transferred to your work piece through a number of channels all working together. First you have a connection from the actual vacuum pump to the machine table. Depending on how many zones […]

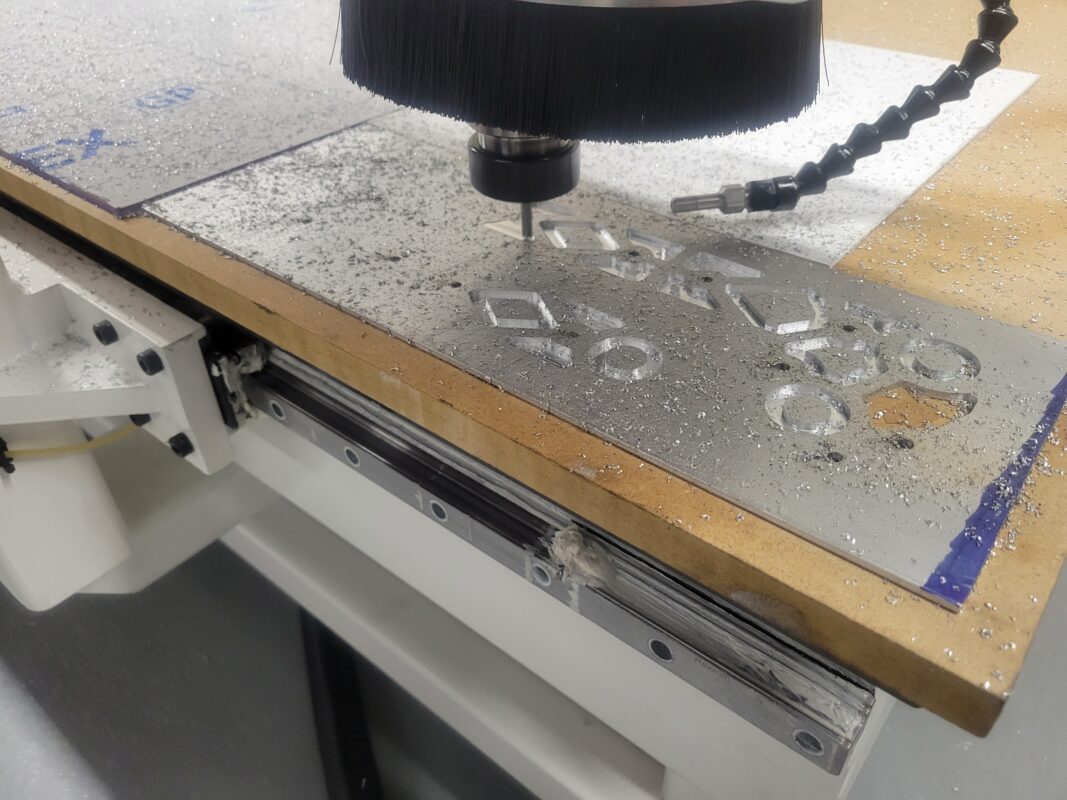

Prototyping a wide range of products and parts becomes easier with the use of a CNC router. The high level of precision and repeatability offered by a CNC router allows you to create complex and detailed prototypes with a high level of accuracy and consistency. Making small edits in your design can translate directly into […]

A CNC router is a powerful tool that can greatly improve the efficiency and precision of sign making operations. One of the primary benefits of using a CNC router for sign making is the ability to create custom designs and shapes with a high level of precision. By inputting the desired dimensions and geometry into […]