Hard Woods, Metals, Plastics, Router Bits, Signage

Using a 3-Axis CNC Router for Signmaking

A CNC router is a powerful tool that can greatly improve the efficiency and precision of sign making operations.

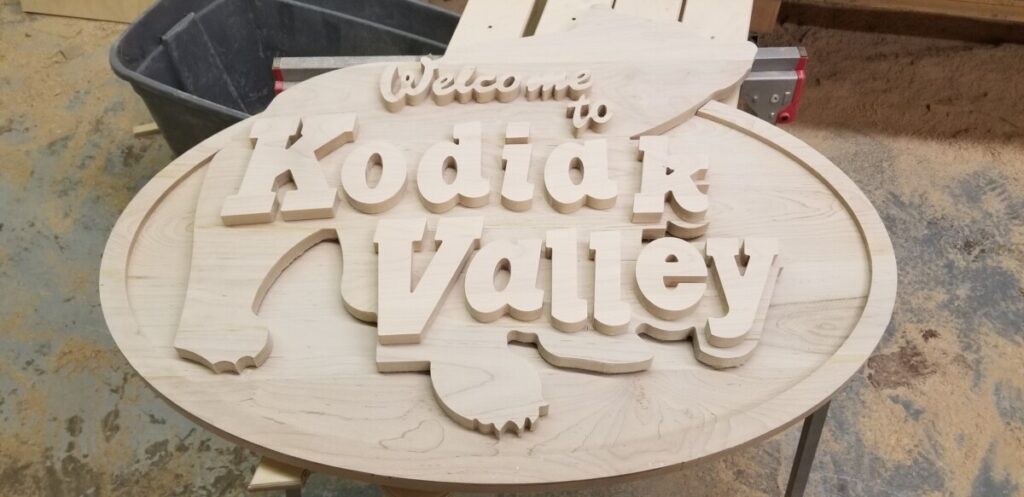

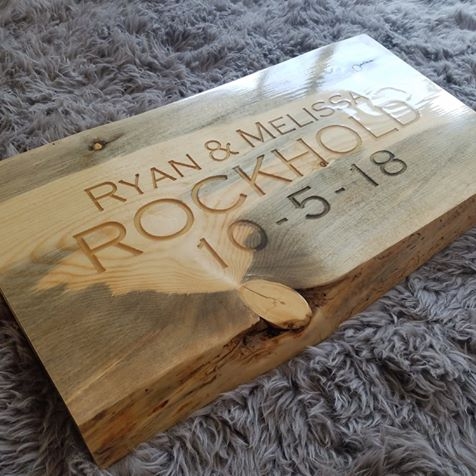

One of the primary benefits of using a CNC router for sign making is the ability to create custom designs and shapes with a high level of precision. By inputting the desired dimensions and geometry into the router using computer-aided design (CAD) software, you can create a wide range of sign shapes and sizes with minimal setup time. The CNC shines when you start creating complex shapes such as what may be found in a company logo or in a wood grain background. Layering letters in the same sign is nearly impossible for a human to do consistently without the help of a machine.

Some popular sign styles that a CNC router can help produce include:

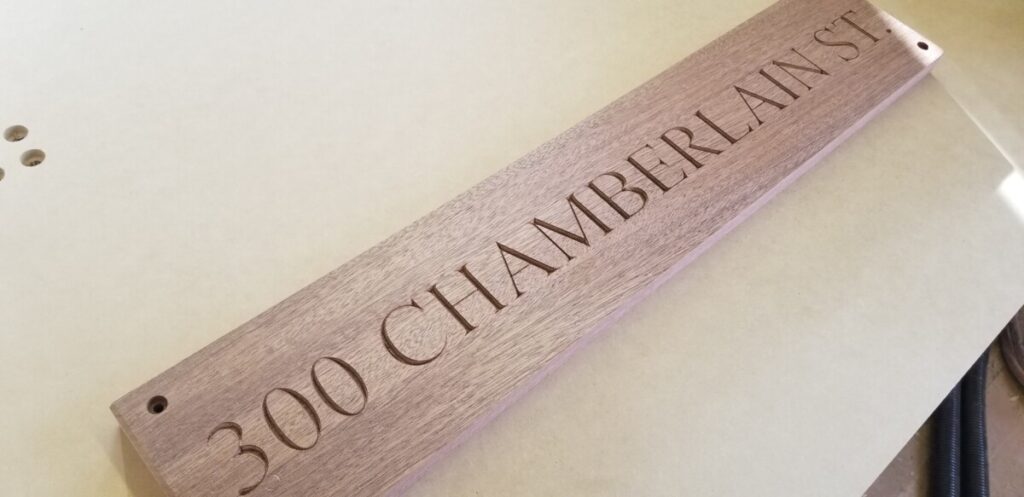

Custom shaped signs: A CNC router can be used to create custom shaped signs in a wide range of materials, such as wood, plastic, and metal. By inputting the desired dimensions and geometry into the router using computer-aided design (CAD) software, you can create signs in any shape or size with minimal setup time.

Dimensional letters: A CNC router can be used to create custom dimensional letters in a wide range of materials, such as acrylic, foam, and wood. This allows you to create signs with a three-dimensional appearance, adding depth and interest to your designs.

Cabinet signs: A CNC router can be used to create custom cabinet signs in a wide range of materials, such as wood, plastic, and metal. These signs are typically mounted on a substrate, such as MDF or particleboard, and can be finished with a wide range of materials, including paint, vinyl, and laminates.

Metal signs: A CNC router can be used to create custom metal signs in a wide range of materials, such as aluminum, brass, and steel. This allows you to create high-quality signs with a professional appearance that are

The ability to receive client files of logos, shapes, sizes etc… and directly translate that onto material becomes incredibly easy with the use of a CNC. Pop up pins add another layer of ease as you can now use the corner of your machine as a reference spot to produce large production runs of similar sized signs.

-

Product on sale

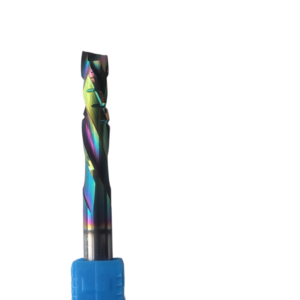

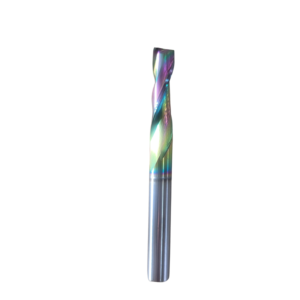

Front Range CNC 3/8″ Rainbow Heat Coated Two Flute Roughing Compression Chipbreaker Bit, Plywood 3/8 D X 1 CH X 3/8 SHK X 3 Inch Long Roughing Compression Chipbreaker Router BitOriginal price was: $79.99.$49.99Current price is: $49.99.

Front Range CNC 3/8″ Rainbow Heat Coated Two Flute Roughing Compression Chipbreaker Bit, Plywood 3/8 D X 1 CH X 3/8 SHK X 3 Inch Long Roughing Compression Chipbreaker Router BitOriginal price was: $79.99.$49.99Current price is: $49.99. -

Product on sale

Front Range CNC 3/8″ Nano Blue Heat Coated Two Flute Compression Bit, Plywood 3/8 D X 1.25 CH X 3/8 SHK X 3 Inch Long Compression Router BitOriginal price was: $79.99.$49.99Current price is: $49.99.

Front Range CNC 3/8″ Nano Blue Heat Coated Two Flute Compression Bit, Plywood 3/8 D X 1.25 CH X 3/8 SHK X 3 Inch Long Compression Router BitOriginal price was: $79.99.$49.99Current price is: $49.99. -

Product on sale

Front Range CNC 3/8″ Rainbow Heat Coated Two Flute Compression Chipbreaker Bit, Plywood 3/8 D x 1 CH x 3/8 SHK x 3 Inch Long Compression Chipbreaker Router BitOriginal price was: $79.99.$58.99Current price is: $58.99.

Front Range CNC 3/8″ Rainbow Heat Coated Two Flute Compression Chipbreaker Bit, Plywood 3/8 D x 1 CH x 3/8 SHK x 3 Inch Long Compression Chipbreaker Router BitOriginal price was: $79.99.$58.99Current price is: $58.99. -

Product on sale

Front Range CNC 3/8″ Rainbow Heat Coated Two Flute Downcut Bit, Plywood 3/8 D x 1.5 x 3/8 SHK x 3Inch Long Downcut Router BitOriginal price was: $79.99.$49.99Current price is: $49.99.

Front Range CNC 3/8″ Rainbow Heat Coated Two Flute Downcut Bit, Plywood 3/8 D x 1.5 x 3/8 SHK x 3Inch Long Downcut Router BitOriginal price was: $79.99.$49.99Current price is: $49.99. -

Product on sale

Front Range CNC 1/4″ Rainbow Heat Coated Two Flute Compression Chipbreaker Bit, Plywood 1/4 D x 1 CH x 1/4 SHK x 2 1/2 Inch Long Compression Router BitOriginal price was: $39.99.$19.99Current price is: $19.99.

Front Range CNC 1/4″ Rainbow Heat Coated Two Flute Compression Chipbreaker Bit, Plywood 1/4 D x 1 CH x 1/4 SHK x 2 1/2 Inch Long Compression Router BitOriginal price was: $39.99.$19.99Current price is: $19.99. -

Product on sale

HSK 63F ER32 70L Tool HolderOriginal price was: $99.99.$89.99Current price is: $89.99.

HSK 63F ER32 70L Tool HolderOriginal price was: $99.99.$89.99Current price is: $89.99. -

Product on sale

Front Range CNC 1/4″ Rainbow Heat Coated Two Flute Up Cut Bit, Plywood 1/4 D x 1 CH x 1/4 SHK x 2 1/2 Inch Long Router BitOriginal price was: $39.99.$19.99Current price is: $19.99.

Front Range CNC 1/4″ Rainbow Heat Coated Two Flute Up Cut Bit, Plywood 1/4 D x 1 CH x 1/4 SHK x 2 1/2 Inch Long Router BitOriginal price was: $39.99.$19.99Current price is: $19.99. -

Product on sale

Front Range CNC 1/4″ Rainbow Heat Coated Two Flute Down Cut Bit, Plywood 1/4 D x 1 CH x 1/4 SHK x 2 1/2 Inch Long Router BitOriginal price was: $39.99.$19.99Current price is: $19.99.

Front Range CNC 1/4″ Rainbow Heat Coated Two Flute Down Cut Bit, Plywood 1/4 D x 1 CH x 1/4 SHK x 2 1/2 Inch Long Router BitOriginal price was: $39.99.$19.99Current price is: $19.99. -

Product on sale

Front Range CNC 3/8″ Rainbow Heat Coated Two Flute Compression Bit, Plywood 3/8 D x 2 CH x 3/8 SHK x 3 1/2 Inch Long Compression Router BitOriginal price was: $79.99.$58.99Current price is: $58.99.

Front Range CNC 3/8″ Rainbow Heat Coated Two Flute Compression Bit, Plywood 3/8 D x 2 CH x 3/8 SHK x 3 1/2 Inch Long Compression Router BitOriginal price was: $79.99.$58.99Current price is: $58.99.