Pioneer Series 5x10

Welcome to precision and affordability tailored for compact spaces with the 5x10 model of the Pioneer Series 3-axis CNC routers by Front Range CNC. This model is a testament to our commitment to bringing advanced CNC technology to a wide range of settings, from small workshops to larger industrial environments. The 5x10 Pioneer router, meticulously crafted with attention to detail, stands out for its ability to handle a diverse range of materials and applications despite its compact size. It's the perfect solution for businesses looking to enhance their production capabilities without the need for extensive space or a hefty investment. Experience the balance of performance and cost-effectiveness with the 5x10 Pioneer, and see how it can revolutionize your operations with its versatility, reliability, and ease of use. Discover the features and capabilities of this model and how it exemplifies our dedication to making sophisticated CNC technology accessible and practical for all.

Production Ready Starting at $58,080

Finance as low as $1,280 a month

The Ultimate Machine for Just About...Anything

Maximizing Efficiency: Time-Saving Features of the Pioneer Series

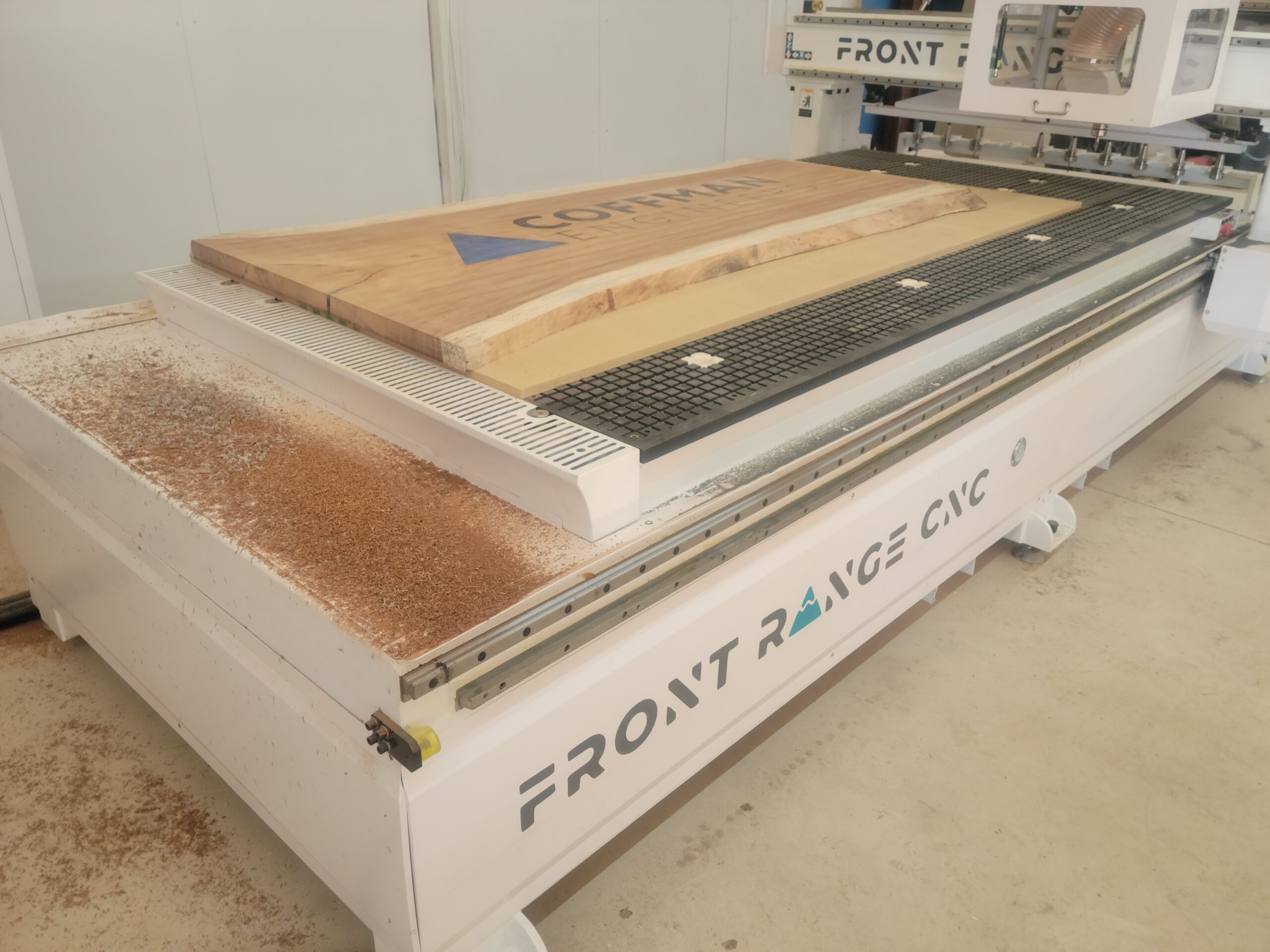

The Dust Sweep Arm on the Pioneer Series of 3-axis CNC routers is a significant feature designed to enhance the machine's efficiency and the operator's working environment. Here's an elaboration on its functionality and benefits:

- Automated Cleaning Process: The Dust Sweep Arm is an automated system designed to remove dust and debris directly from the cutting area during operation. This feature ensures that the work surface remains clean without manual intervention, enhancing the precision of cuts and engravings.

- Improved Air Quality and Visibility: By efficiently removing dust as it is generated, the Dust Sweep Arm significantly improves the air quality in the workspace. This is not only beneficial for the health and safety of operators but also provides better visibility of the work process, allowing for more precise adjustments and monitoring.

- Extended Machine Life: Dust and debris can be detrimental to the mechanical and electronic components of CNC routers. The Dust Sweep Arm helps in maintaining a cleaner machine, reducing the wear and tear on crucial parts and potentially extending the overall lifespan of the machine.

- Reduction in Downtime: Frequent stops for cleaning can significantly slow down production. The automated cleaning process of the Dust Sweep Arm minimizes such interruptions, allowing for continuous operation and thus increasing overall productivity.

- Enhanced End-Product Quality: By maintaining a clean cutting area, the Dust Sweep Arm helps in ensuring that the final products are free from dust-related imperfections. This is particularly important for high-quality finishes and detailed work.

- Cost-Effective Maintenance: Regular cleaning and maintenance of CNC routers can be time-consuming and costly. The Dust Sweep Arm reduces the need for frequent manual cleaning, saving both time and maintenance costs in the long run.

The Syntec complete control system utilizes high speed M3 connection for a better cut

The Pioneer Series 3-axis CNC routers, featuring the high-speed M3 connection of a full Syntec system, exemplify precision in motion. This advanced connectivity ensures ultra-smooth and highly accurate movements, essential for intricate designs and precision work, especially on materials like aluminum. The high-speed M3 connection enables the CNC router to interpret and execute commands rapidly, reducing lag and enhancing responsiveness.

This is particularly evident in operations involving complex curves and detailed patterns on aluminum pieces, where the precision of movement is paramount. The Syntec system's superior data handling capabilities allow for intricate designs to be executed flawlessly, with smooth edges and precise dimensions. This combination of high-speed data transfer and precise control results in exceptional detailing and quality finishes, making the Pioneer series an ideal choice for projects requiring the utmost accuracy and finesse. Whether it's delicate artwork or industrial-grade metalwork, the Pioneer series, with its full Syntec system and high-speed M3 connection, delivers unparalleled precision and reliability.

Boasting a fully precision-milled steel frame finished on an aerospace mill, represent the pinnacle of stability and durability in CNC machining

- Precision and Stability with Aerospace Mill Finishing: The frame, finished on an aerospace mill, is manufactured with exceptional accuracy. This meticulous process ensures the frame's stability, which is essential for consistent, high-quality cuts. The precision in construction significantly enhances the machine's overall stability, vital for achieving uniform results.

- Vibration Dampening from Heavy Steel Frame: Weighing 5,000lbs, the frame's substantial mass is instrumental in dampening operational vibrations. Vibrations can negatively impact work quality, but the heavy steel frame of the 5x10 model effectively absorbs these disturbances. This results in smoother operations and more precise cuts, especially crucial when working with intricate designs.

- Durability and Longevity: The high-grade materials and construction techniques used in the frame make it inherently durable. This robust build translates to a longer lifespan of the machine, positioning it as a reliable long-term investment. It's well-suited to withstand the demands of continuous industrial use while maintaining consistent performance and precision.

- Handling Complex Materials: The stability provided by the heavy frame is particularly valuable when machining challenging materials, such as metals or dense hardwoods. The frame's robustness ensures that the machine can endure the stress of machining these materials without sacrificing accuracy or the quality of the output.

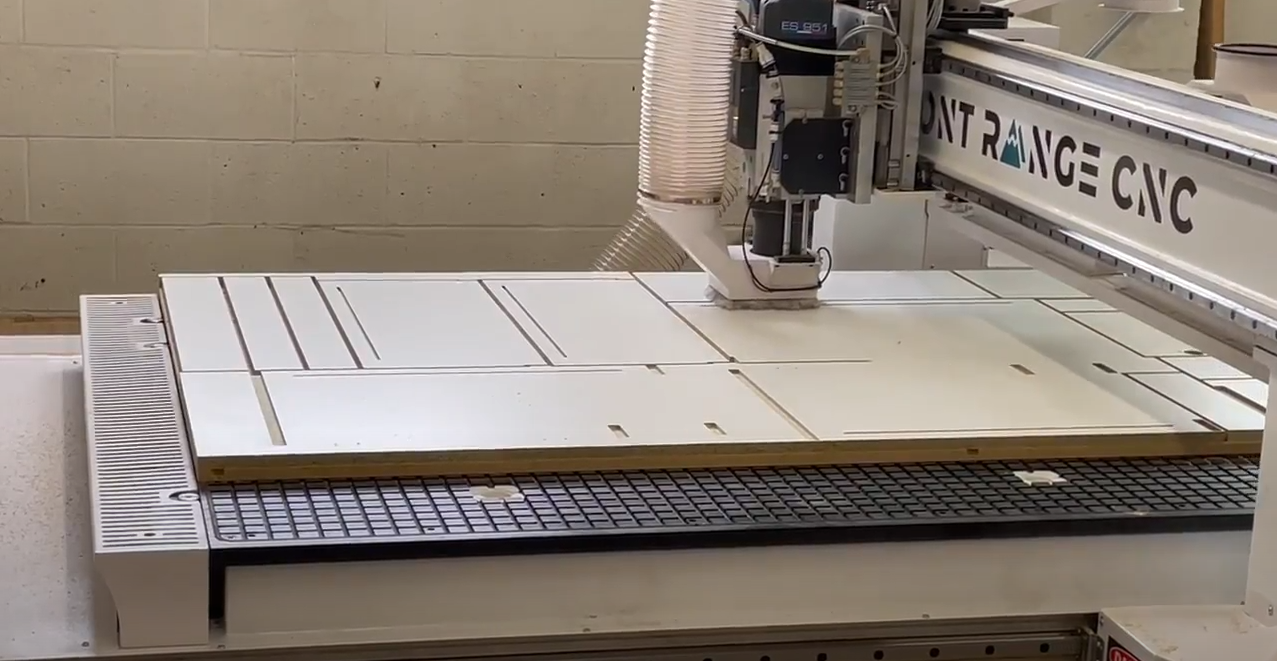

Optimally designed for cabinetry, offering unparalleled precision and efficiency in this specialized field.

- Precision and Accuracy: The high degree of accuracy provided by the Pioneer Series is crucial for cabinetry, where precise cuts and joints are essential. The machine’s advanced control system and robust construction ensure that each piece is cut to exact specifications, resulting in seamless assembly.

- Versatility in Material Handling: Cabinetry often involves working with a variety of materials, from hardwoods to engineered woods like plywood or MDF. The Pioneer Series is well-equipped to handle these diverse materials, maintaining precision and quality in every cut, regardless of the material type.

- Efficient Production: With features like high-speed M3 connections and a user-friendly Syntec control system, the Pioneer Series can significantly speed up production times. This efficiency is key in cabinetry work, where the volume of pieces and the complexity of designs can vary greatly.

- Customization Capabilities: The flexibility of the Pioneer Series allows for easy customization of designs. This is particularly beneficial in cabinetry, where unique dimensions and intricate designs are often required to meet specific customer needs or space constraints.

- Superior Finish Quality: The smooth operation and vibration dampening capabilities of the machine ensure a superior finish quality. This is vital in cabinetry, where the aesthetics of the final product are as important as its functionality.

- Large Working Area: The availability of different size options, including the smaller 4x8 and 5x12 models, provides ample working area for larger cabinet panels, making it easier to produce full-sized components without the need for additional processing.