Fixturing, Hard Woods, Metals, Plastics, Prototyping

3-Axis CNC Router for Prototyping

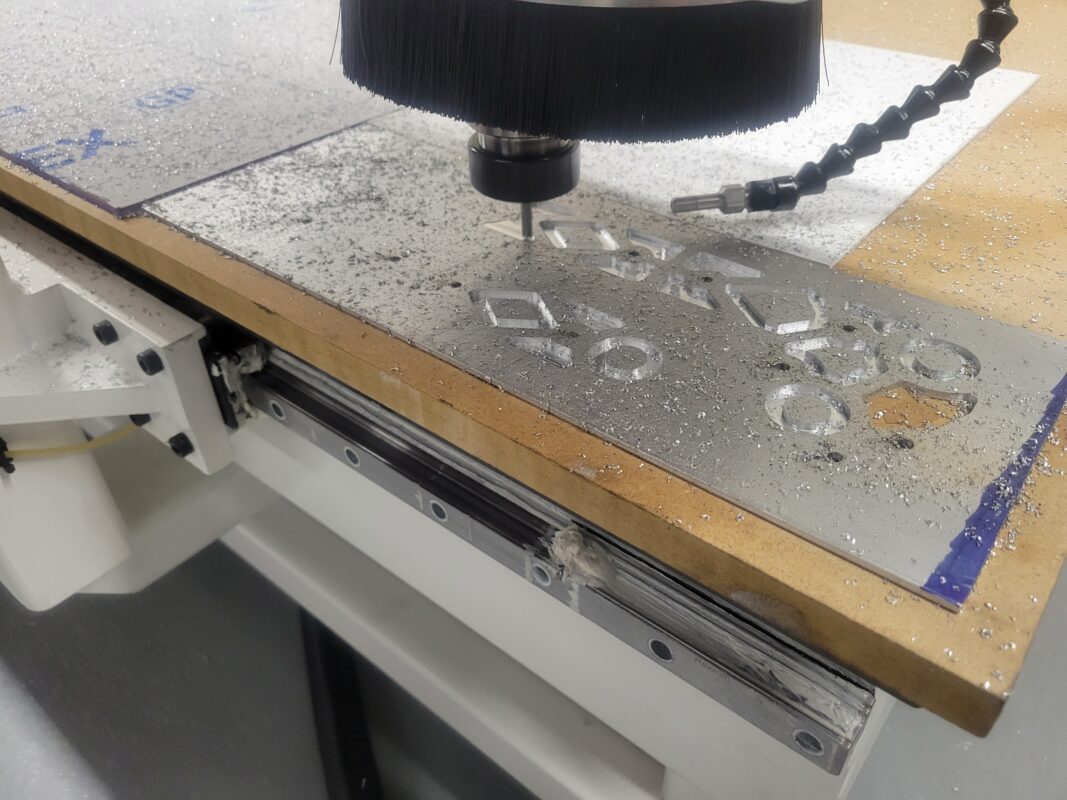

Prototyping a wide range of products and parts becomes easier with the use of a CNC router. The high level of precision and repeatability offered by a CNC router allows you to create complex and detailed prototypes with a high level of accuracy and consistency. Making small edits in your design can translate directly into your next physical prototype. We see this as especially handy when working around dimensions that are not already in a CAD format.

The versatility of being able to drill, slot, pocket, profile allows you to make edits across an entire piece and create a consistent product to test. This allows you to create prototypes with a high level of detail and complexity, including features such as threads, holes, and grooves – all translating into a faster turn around from design to production.

A CNC router becomes a pivotal tool when prototyping for other companies in a job shop role. As long as you have a software you are comfortable with using to create toolpaths, you can receive virtually any design format from your clients to then create a part for them to approve and produce.

Overall, a 3-axis CNC router is a powerful tool that can greatly improve the efficiency and precision of your prototyping operations. Whether you are a professional manufacturer or a DIY enthusiast, a 3-axis CNC router can help you achieve high-quality prototypes with ease.

There are many software programs that can be used to create prototype models for a CNC router. Some of the most common software options include:

Computer-aided design (CAD) software: CAD software allows you to create detailed 2D and 3D models of your prototype. These models can be imported into the CNC router’s control software to generate the toolpaths for machining the prototype. Popular CAD software options include AutoCAD, SolidWorks, and Fusion 360.

Computer-aided manufacturing (CAM) software: CAM software is used to convert the CAD model into the specific toolpaths and instructions required by the CNC router to produce the prototype. This typically involves selecting the appropriate cutting tools, specifying the machining parameters, and generating the toolpaths. Popular CAM software options include Mastercam, HSMWorks, Fusion 360, VCarve Pro, Rhino, and others…

3D modeling software: 3D modeling software allows you to create detailed 3D models of your prototype. These models can be imported into CAD or CAM software for further refinement and toolpath generation. Popular 3D modeling software options include Blender, Maya, and 3ds Max.

Overall, the choice of software will depend on your specific needs and requirements.

-

Product on sale

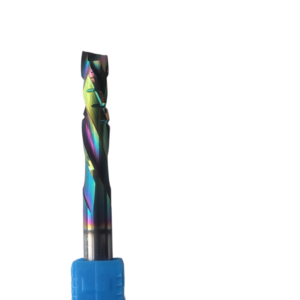

Front Range CNC 3/8″ Rainbow Heat Coated Two Flute Roughing Compression Chipbreaker Bit, Plywood 3/8 D X 1 CH X 3/8 SHK X 3 Inch Long Roughing Compression Chipbreaker Router Bit$49.99

Front Range CNC 3/8″ Rainbow Heat Coated Two Flute Roughing Compression Chipbreaker Bit, Plywood 3/8 D X 1 CH X 3/8 SHK X 3 Inch Long Roughing Compression Chipbreaker Router Bit$49.99 -

Product on sale

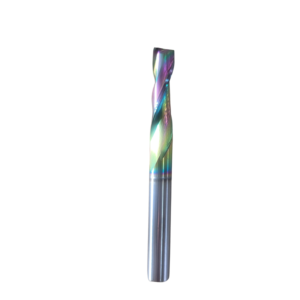

Front Range CNC 3/8″ Nano Blue Heat Coated Two Flute Compression Bit, Plywood 3/8 D X 1.25 CH X 3/8 SHK X 3 Inch Long Compression Router Bit$49.99

Front Range CNC 3/8″ Nano Blue Heat Coated Two Flute Compression Bit, Plywood 3/8 D X 1.25 CH X 3/8 SHK X 3 Inch Long Compression Router Bit$49.99 -

Product on sale

Front Range CNC 3/8″ Rainbow Heat Coated Two Flute Compression Chipbreaker Bit, Plywood 3/8 D x 1 CH x 3/8 SHK x 3 Inch Long Compression Chipbreaker Router Bit$58.99

Front Range CNC 3/8″ Rainbow Heat Coated Two Flute Compression Chipbreaker Bit, Plywood 3/8 D x 1 CH x 3/8 SHK x 3 Inch Long Compression Chipbreaker Router Bit$58.99 -

Product on sale

Front Range CNC 3/8″ Rainbow Heat Coated Two Flute Downcut Bit, Plywood 3/8 D x 1.5 x 3/8 SHK x 3Inch Long Downcut Router Bit$49.99

Front Range CNC 3/8″ Rainbow Heat Coated Two Flute Downcut Bit, Plywood 3/8 D x 1.5 x 3/8 SHK x 3Inch Long Downcut Router Bit$49.99 -

Product on sale

Front Range CNC 1/4″ Rainbow Heat Coated Two Flute Compression Chipbreaker Bit, Plywood 1/4 D x 1 CH x 1/4 SHK x 2 1/2 Inch Long Compression Router Bit$19.99

Front Range CNC 1/4″ Rainbow Heat Coated Two Flute Compression Chipbreaker Bit, Plywood 1/4 D x 1 CH x 1/4 SHK x 2 1/2 Inch Long Compression Router Bit$19.99 -

Product on sale

HSK 63F ER32 70L Tool Holder$89.99

HSK 63F ER32 70L Tool Holder$89.99 -

Product on sale

Front Range CNC 1/4″ Rainbow Heat Coated Two Flute Up Cut Bit, Plywood 1/4 D x 1 CH x 1/4 SHK x 2 1/2 Inch Long Router Bit$19.99

Front Range CNC 1/4″ Rainbow Heat Coated Two Flute Up Cut Bit, Plywood 1/4 D x 1 CH x 1/4 SHK x 2 1/2 Inch Long Router Bit$19.99 -

Product on sale

Front Range CNC 1/4″ Rainbow Heat Coated Two Flute Down Cut Bit, Plywood 1/4 D x 1 CH x 1/4 SHK x 2 1/2 Inch Long Router Bit$19.99

Front Range CNC 1/4″ Rainbow Heat Coated Two Flute Down Cut Bit, Plywood 1/4 D x 1 CH x 1/4 SHK x 2 1/2 Inch Long Router Bit$19.99 -

Product on sale

Front Range CNC 3/8″ Rainbow Heat Coated Two Flute Compression Bit, Plywood 3/8 D x 2 CH x 3/8 SHK x 3 1/2 Inch Long Compression Router Bit$58.99

Front Range CNC 3/8″ Rainbow Heat Coated Two Flute Compression Bit, Plywood 3/8 D x 2 CH x 3/8 SHK x 3 1/2 Inch Long Compression Router Bit$58.99