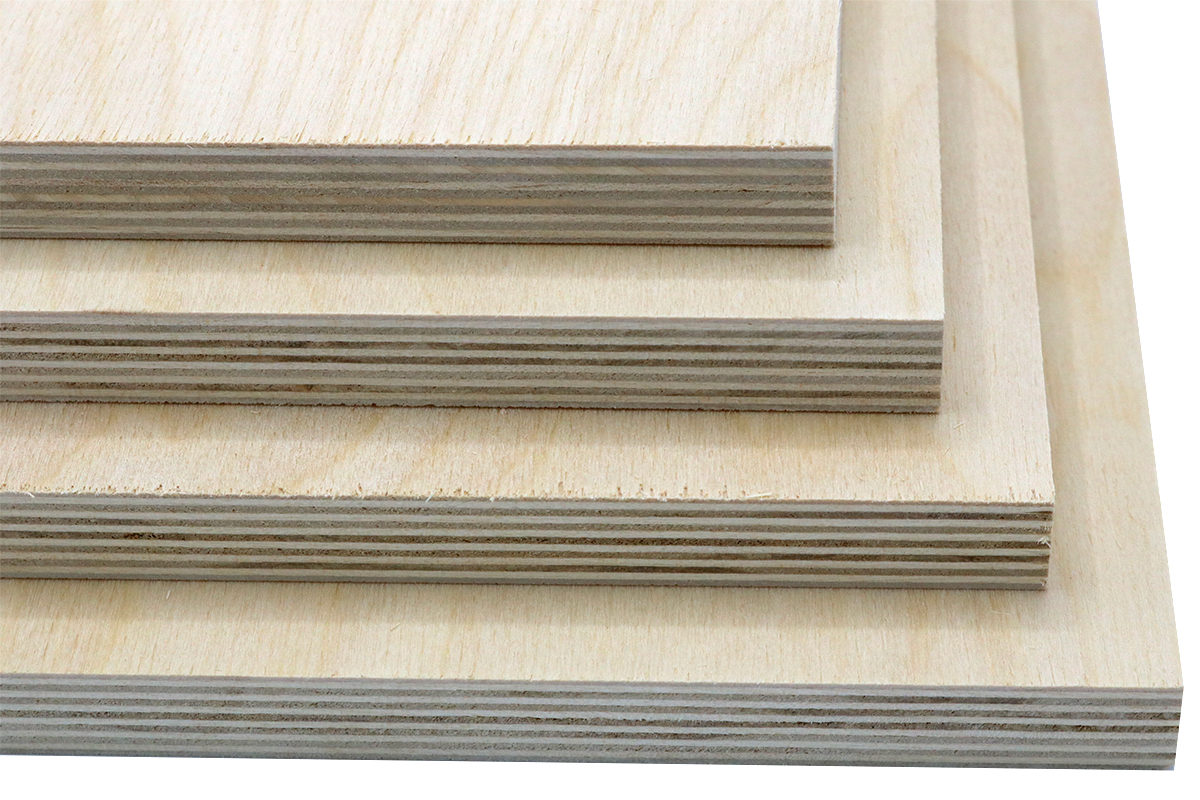

CNC routers and CNC mills are both machines used for cutting materials. Although they share some similarities, there are distinct differences between the two in terms of their design, functionality, and applications. It is important to select the correct machine based on your part size and floor space. Design and Construction: CNC routers typically have […]

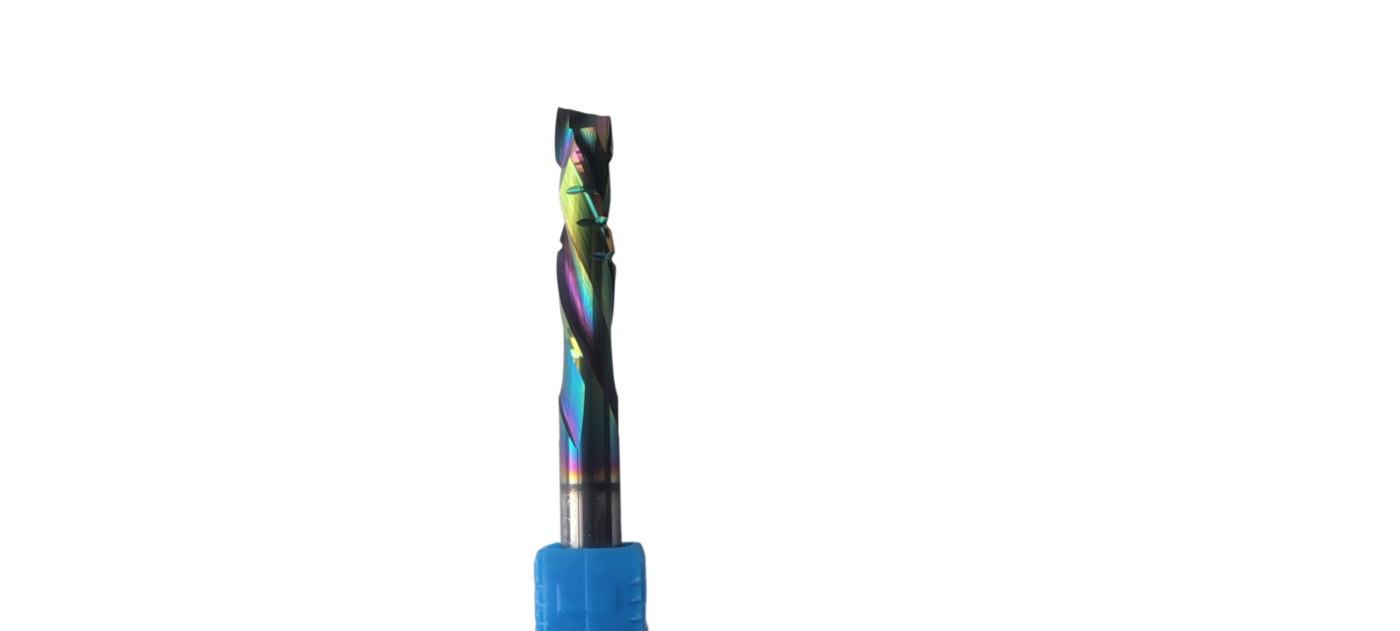

CNC routers have revolutionized the manufacturing industry with their ability to create intricate designs and shapes in various materials with remarkable precision. One critical aspect of a CNC router’s performance is its drive system, which is responsible for translating motor movements into precise linear motion. Two common drive systems used in CNC routers are ballscrew […]

The It can be a big task to transition from one-off projects to production using a CNC router. The associated costs and space needed alone may seem monumental at first glance. Some important things to consider are- Capacity and throughput: Make sure the CNC router can handle the increased workload, which may require upgrading to […]

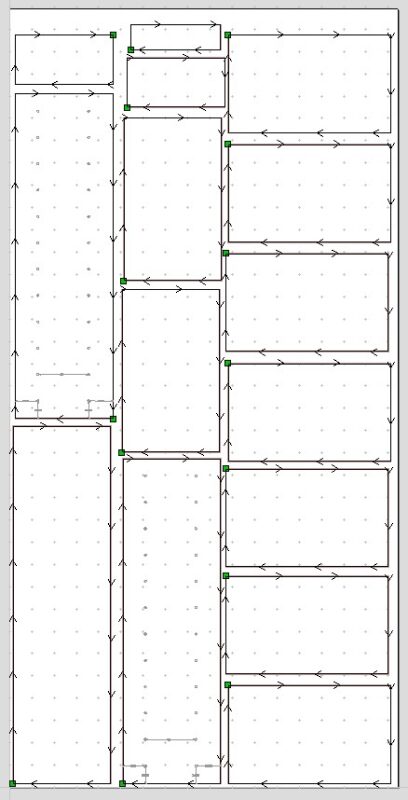

Look ahead functionality is a feature of some industrial CNC router controllers that allows the machine to “look ahead” in the toolpath and anticipate future moves. This can help to improve the efficiency and performance of the CNC router, particularly during high-speed machining operations. Imagine a race car driver analyzing the track as they come […]

Cutting a logo into a live edge slab is easier than you may think when using a CNC router. This is an efficient way to get accurate details to then be filled with epoxy or an inlay. Design the company logo: The first step is to design the company logo and determine the size and […]

- 1

- 2