Uncategorized

Chipbreaker Router Bits: Unleashing the Power of Advanced Cutting Technology

Title: Chipbreaker Compression Router Bits: Unleashing the Power of Advanced Cutting Technology

Introduction:

Router bits play a crucial role in the performance and capabilities of CNC routers and woodworking machines. With the wide variety of router bit designs available, selecting the right one for a specific task can greatly impact the quality of your projects. One advanced router bit design that has gained popularity among woodworkers and fabricators is the chipbreaker compression router bit. In this blog post, we’ll explore what chipbreaker compression router bits are, their unique features, and the advantages they offer over traditional router bits.

What is a Chipbreaker Compression Router Bit?

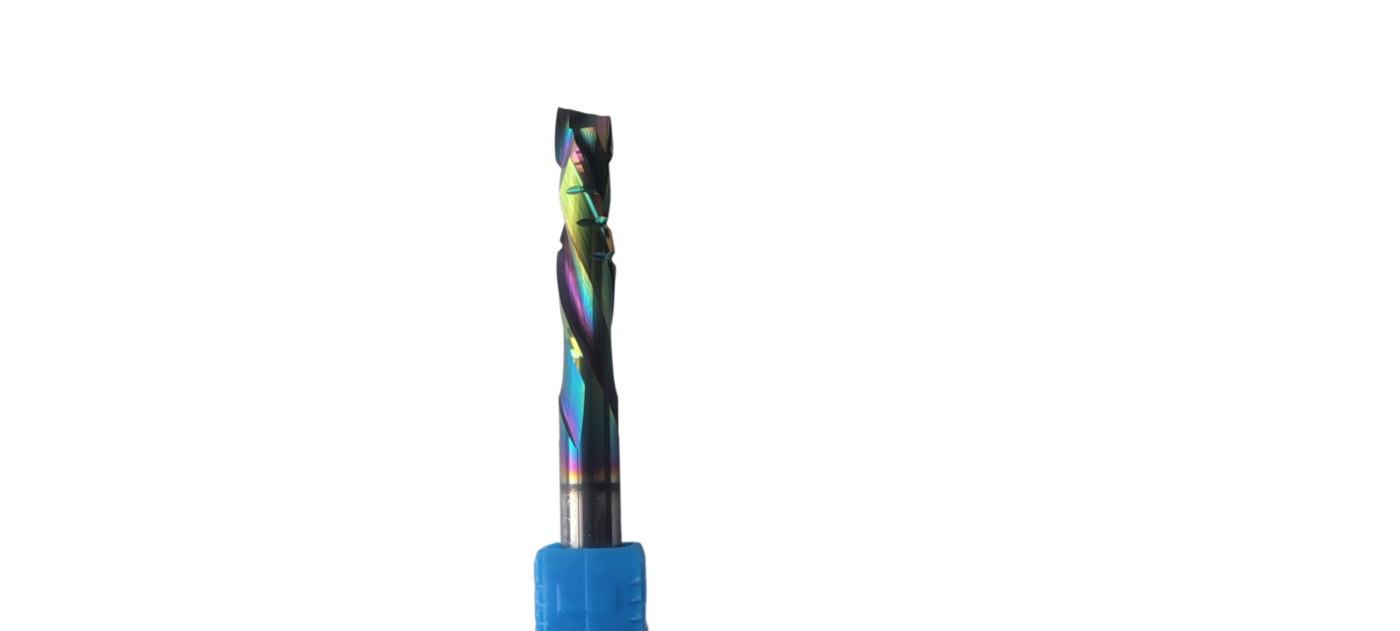

A chipbreaker compression router bit is a specialized cutting tool designed to offer superior performance in specific cutting applications. It combines the best of both worlds by incorporating the features of compression bits and chipbreaker technology. The compression aspect of the bit features an upcut and downcut spiral geometry, which ensures clean cuts on both the top and bottom surfaces of the workpiece. The chipbreaker element, on the other hand, consists of notches or serrations along the cutting edges that help break chips into smaller pieces, improving chip evacuation and reducing cutting resistance.

Advantages of Chipbreaker Compression Router Bits:

a) Reduced Chip Size and Improved Chip Evacuation:

The chipbreaker design of these router bits breaks the chips or shavings into smaller pieces during the cutting process. This feature prevents chips from clogging the cutting path, wrapping around the bit, or sticking to the workpiece, which can lead to poor surface finishes and increased cutting resistance. Efficient chip evacuation also helps minimize heat buildup, protecting both the router bit and the workpiece from heat-related damage.

b) Enhanced Surface Finish:

Chipbreaker compression router bits provide exceptionally clean cuts on both the top and bottom surfaces of the workpiece, thanks to their compression geometry. This results in reduced tear-out and minimized need for sanding or additional finishing, ultimately saving time and improving the overall appearance of your projects.

c) Increased Tool Life and Durability:

By breaking chips into smaller pieces and reducing heat buildup, chipbreaker compression router bits experience less wear and tear during the cutting process. This translates to extended tool life and increased durability, making them a cost-effective choice in the long run.

d) Versatility in Material Selection:

Chipbreaker compression router bits are well-suited for a variety of materials, including hardwood, softwood, plywood, MDF, laminates, and even some plastics. This versatility makes them a valuable addition to any woodworker’s or fabricator’s tool arsenal.

e) Improved Cutting Efficiency:

The combination of compression geometry and chipbreaker technology enables these router bits to cut through materials with greater efficiency. This can result in faster cutting speeds and reduced production time, which is particularly beneficial for businesses or high-volume projects.

Conclusion:

Chipbreaker compression router bits are an innovative cutting tool solution that offers numerous advantages over traditional router bits. By combining the benefits of compression geometry with the power of chipbreaker technology, these advanced router bits deliver superior cutting performance, improved surface finish, and longer tool life. If you’re looking to elevate your CNC routing or woodworking projects, consider incorporating chipbreaker compression router bits into your toolkit to experience the difference that advanced cutting technology can make.