Cabinetry, Plywood, Uncategorized

The Advantages of Baltic Birch Plywood for CNC Routing: Why It’s Your Go-To Choice

When it comes to CNC routing, the choice of material can significantly impact the quality of the finished product. Among the wide variety of plywood options available, Baltic birch plywood stands out as the top choice for CNC routing projects. In this blog post, we’ll discuss the numerous benefits of using Baltic birch plywood over other varieties, highlighting why it’s the go-to material for your CNC router.

Superior Strength and Stability

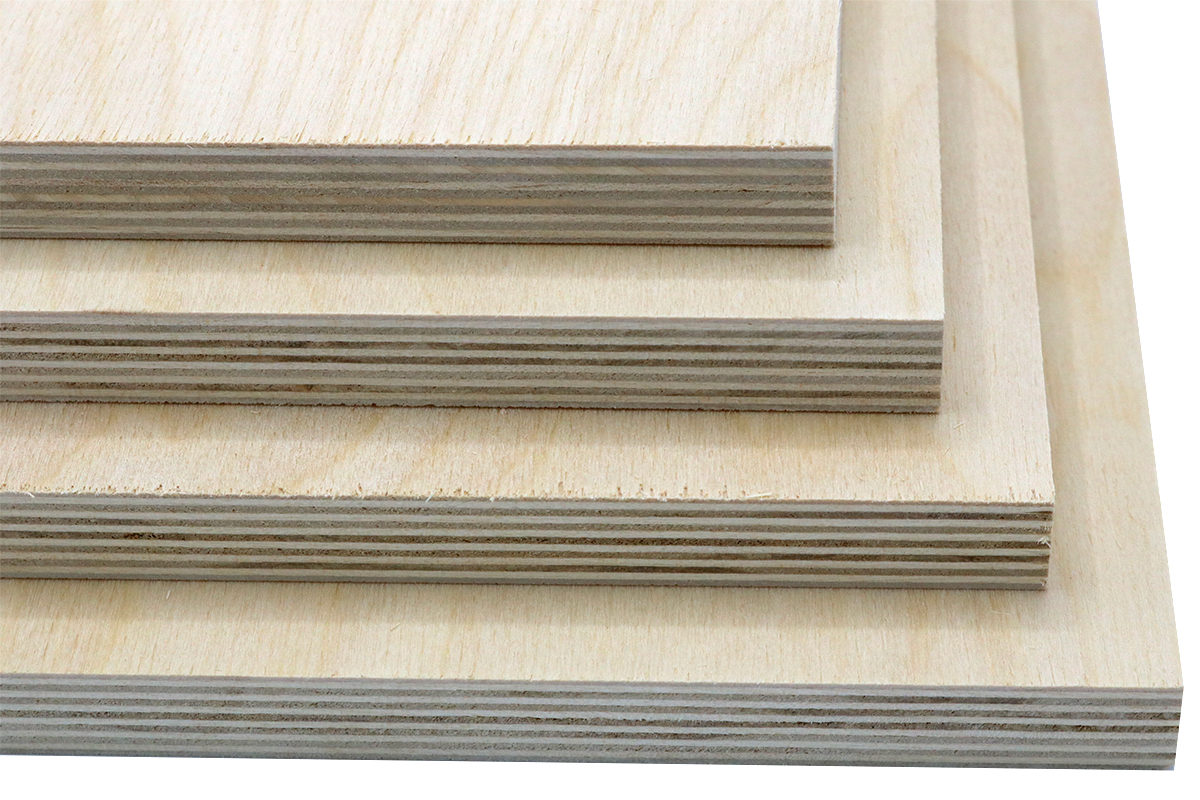

Baltic birch plywood is known for its exceptional strength and stability, making it ideal for CNC routing projects. The multiple layers of high-quality birch veneer in its composition contribute to its impressive rigidity, reducing the chances of warping or bending during the routing process. This stability ensures cleaner cuts and an overall better finish for your projects.

Uniform Thickness and Consistent Layers

One of the key advantages of Baltic birch plywood is its uniform thickness and consistent layers. The manufacturing process of Baltic birch plywood involves using thinner, more consistent layers of veneer compared to other plywood varieties. This results in a more even distribution of strength across the entire sheet, making it easier for the CNC router to produce accurate and precise cuts.

Minimal Voids and Defects

Baltic birch plywood has fewer voids and defects than other types of plywood, ensuring a smoother and more consistent surface for your CNC projects. The presence of voids or defects can cause tear-outs or rough edges during the CNC routing process. The high-quality construction of Baltic birch plywood minimizes these issues, leading to a better finish and increased durability of the final product. When machining baltic birch plywood you can be more aggressive with your cuts as the likelihood of tear-out is so much less.

Excellent Surface Quality

The smooth and consistent surface of Baltic birch plywood makes it an excellent choice for projects that require a high-quality finish. The fine grain structure and minimal surface defects make it easy to paint, stain, or apply a clear finish. This allows you to create visually appealing products that showcase the natural beauty of the wood grain or match your desired color scheme.

Versatility

Baltic birch plywood’s versatility makes it suitable for a wide range of applications, from woodworking and cabinetry to prototyping and sign making. Its strength, stability, and surface quality make it an ideal material for use with a CNC router, allowing you to create intricate designs and complex shapes with ease.

Baltic birch plywood offers numerous advantages for CNC routing over other varieties of plywood. The major downside is availability and price depending on what area you are in. Another key factor to consider is that of sizing as most baltic birch plywood comes standard in 5’x5′ increments. This is an important consideration when you are deciding on a CNC router as a 4’x8′ CNC might be a good choice now but could be a limitation if you start to work with baltic birch plywood more consistently.