Truck Bed Storage using CNC Router

Creating a truck bed storage system is a good learning project that is popular throughout the USA. This may provide for additional local income from Facebook Marketplace sales or Craigslist commissions. The first step is to take measurements of your truck bed. This is a crucial first step in this process as all truck beds […]

Look ahead functionality in industrial CNC Router Controllers

Look ahead functionality is a feature of some industrial CNC router controllers that allows the machine to “look ahead” in the toolpath and anticipate future moves. This can help to improve the efficiency and performance of the CNC router, particularly during high-speed machining operations. Imagine a race car driver analyzing the track as they come […]

3-Axis CNC Router for Closet Production

Efficiently building closets on a large scale can often times come down to how efficient you are with what tools you have access to. A CNC router is a great way to cut accurate cabinets efficiently and pairing this with dedicated closet design software really takes this to the next level! One of the primary […]

3-Axis CNC Router for Woodworking

A 3-axis CNC router can be an amazing tool for taking your woodworking business to the next level. It is equipped with a cutting tool that is mounted on a moveable arm, which is controlled by a computer to move in three different directions: the X-axis, the Y-axis, and the Z-axis. This allows the machine […]

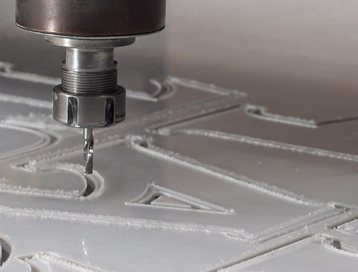

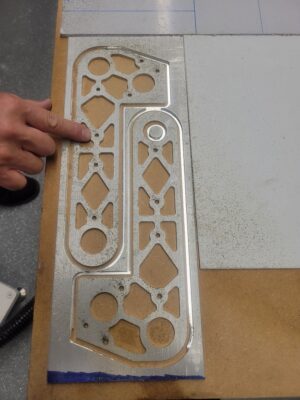

3-Axis CNC Router for Plastics

A 3-axis CNC router cuts, shapes, and machines plastic materials with precision and repeatability. Whether you are a professional manufacturer or a DIY enthusiast, this tool can help you achieve precise and consistent results with minimal waste. CAD software enables you to input exact dimensions and geometry for creating complex shapes and parts with a […]

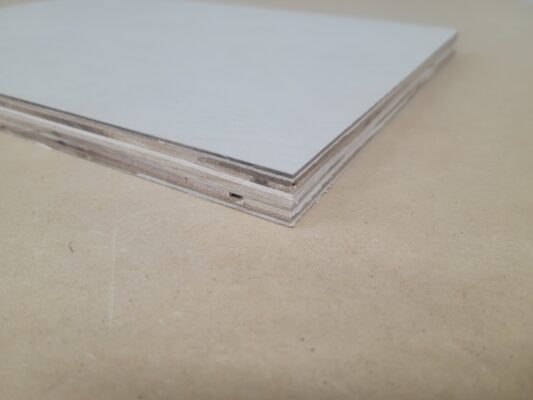

Utilizing 1/4 Compression Router Bit in 3/4 Plywood on a CNC Router

Selecting the right tool for the job is crucial for achieving a high-quality finish. One tool that can be particularly useful in certain situations is a 1/4″ compression bit. These bits are specifically designed for cutting through thicker materials, such as 3/4″ plywood, with minimal effort and maximum precision. The unique shape of the compression […]

Cutting a company logo into a live edge slab using a CNC router

Cutting a logo into a live edge slab is easier than you may think when using a CNC router. This is an efficient way to get accurate details to then be filled with epoxy or an inlay. Design the company logo: The first step is to design the company logo and determine the size and […]

The Benefits of Using a CNC Router in the Cabinet Industry

CNC Routers have had a huge impact on the cabinet industry since their introduction. We have come a long way since the pod and rail style machines the industry started on. Here are some of the top benefits of using a CNC router for cabinet production: Accuracy- CNC routers are highly accurate and precise, allowing […]

Plastic CNC Router Cutting Tips

Here are some tips for cutting plastic using a 3 axis CNC router: -Use a sharp, single-flute end mill specifically designed for cutting plastic.-Use a lower spindle speed and apply more pressure to ensure a clean cut.-Use a low feed rate to prevent the plastic from melting or tearing.-Use a shallow depth of cut to […]

- « Previous

- 1

- 2

- 3

- Next »