Metals, Prototyping, Router Bits

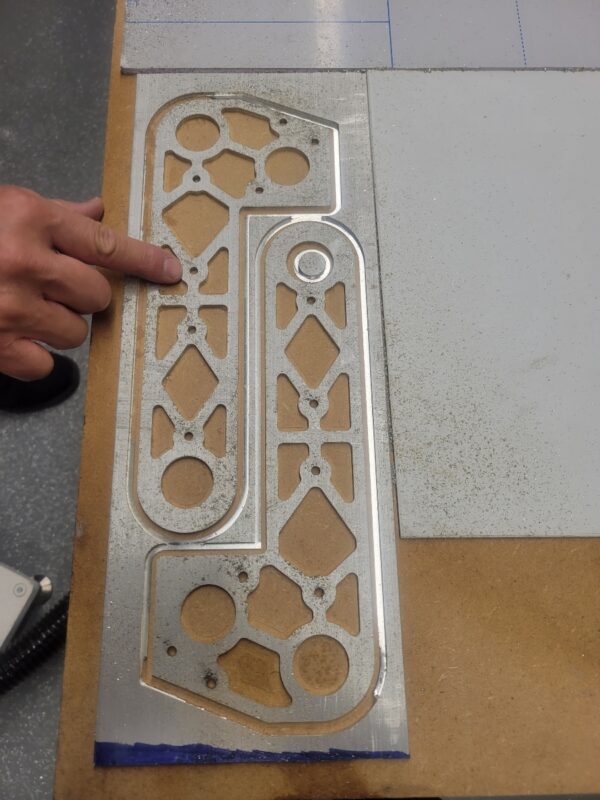

3-Axis CNC Router for Aluminum

A 3-axis CNC router is an essential tool for cutting, shaping, and machining aluminum materials with precision and repeatability. Aluminum is especially telling of machine accuracies/inaccuracies as it is an xtremely stable material.

CNC routers are well-suited for creating complex parts and shapes out of aluminum that would be difficult to achieve using traditional methods. The ability to input exact dimensions and geometry using computer-aided design (CAD) software allows you to create parts with tight tolerances and smooth finishes.

In addition to cutting and shaping, a 3-axis CNC router can also be used for machining operations such as drilling, milling, and tapering. This makes it possible to create a wide range of complex parts and components, such as gears and sprockets, with a high level of accuracy.

It is important to note that aluminum can be more challenging to machine than some other materials due to its high strength and hardness. As a result, specialized tooling and cutting strategies may be required to achieve the desired results. Using appropriate lubricants and coolants can also help to reduce heat and wear on the cutting tools.

Overall, a 3-axis CNC router is a powerful tool that can greatly improve the efficiency and precision of your aluminum machining operations. Whether you are a professional manufacturer or a DIY enthusiast, a 3-axis CNC router is an essential tool for achieving high-quality results.

Lubricants, such as coolants and cutting fluids, are often used in CNC machining operations to help reduce heat and wear on the cutting tools, as well as to improve surface finish and prolong tool life. A misting system, such as a UNIST system, can be used to apply these lubricants in a controlled manner during the machining process.

In the context of CNC machining, a misting system refers to a system that uses compressed air to atomize a liquid lubricant into a fine mist, which is then directed onto the cutting tool and workpiece. This can help to reduce the heat and friction generated during the machining process, which can in turn improve the quality and accuracy of the finished parts.

Overall, a misting system can be a useful tool for improving the efficiency and quality of CNC machining operations. It is important to select the appropriate lubricant and properly maintain the misting system to ensure optimal performance.