Plastics, Prototyping, Router Bits, Signage, Toolpaths

Plastic CNC Router Cutting Tips

Here are some tips for cutting plastic using a 3 axis CNC router:

-Use a sharp, single-flute end mill specifically designed for cutting plastic.

-Use a lower spindle speed and apply more pressure to ensure a clean cut.

-Use a low feed rate to prevent the plastic from melting or tearing.

-Use a shallow depth of cut to prevent the end mill from breaking or delaminating the plastic.

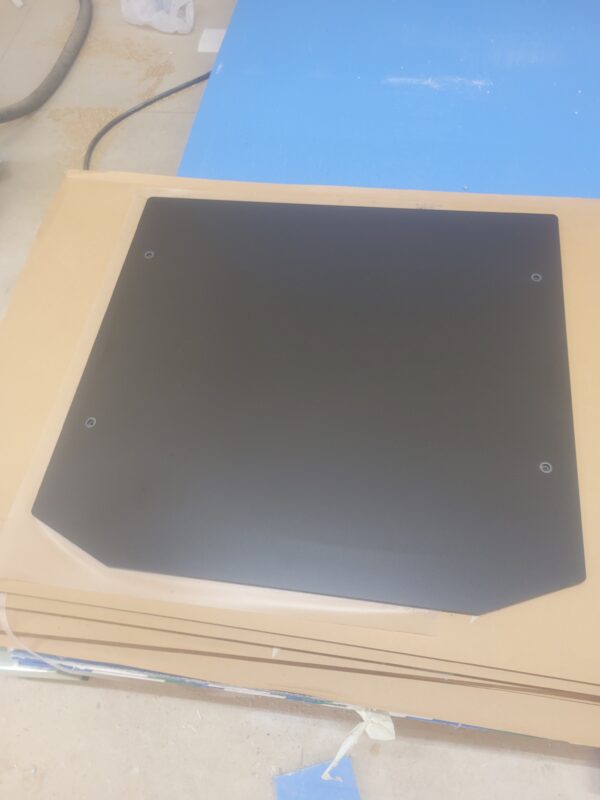

-Use a vacuum table or hold-down clamps to secure the plastic to the bed of the CNC router.

-Use appropriate cutting parameters for the specific type of plastic you are working with.

-Use a slow ramp-in and ramp-out speed to prevent the plastic from cracking or delaminating at the entry and exit points of the cut.

We find the biggest determinant to getting a nice, clean final product is sharpness of bit. Out heat coated single-flute endmills funnel material out and stay dissipate heat. These bits are ideal for cutting plastic.

A simple strategy to help with your edge finish in nearly every plastic is to utilize a final cleanup pass. Imagine you are cutting a 12″ diameter circle out of PVC. A great way to ensure your final product has a nice edge is to make your initial cut at 12.005″ thick in multiple passes. Then do a final full depth cut at your preferred final diameter of 12″ and do this at a full depth. This will eliminate tool marks and give you a consistent edge finish.