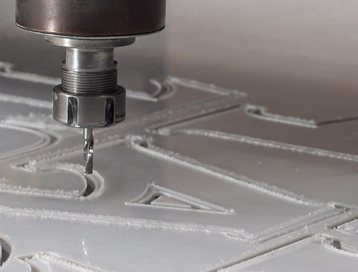

Plastics, Prototyping, Router Bits

3-Axis CNC Router for Plastics

A 3-axis CNC router cuts, shapes, and machines plastic materials with precision and repeatability. Whether you are a professional manufacturer or a DIY enthusiast, this tool can help you achieve precise and consistent results with minimal waste.

CAD software enables you to input exact dimensions and geometry for creating complex shapes and parts with a high level of precision. This makes 3-axis CNC routers ideal for industries such as aerospace and automotive where precision is crucial.

In addition to cutting and shaping, a 3-axis CNC router can also perform machining operations such as drilling, milling, and tapering. This allows you to create a wide range of mechanical components, such as gears and sprockets, with a high level of accuracy.

Overall, a 3-axis CNC router is a powerful tool that improves the efficiency and precision of plastic machining operations. It is an essential tool for professionals and DIY enthusiasts alike who want to achieve high-quality results.

Overall, a 3-axis CNC router is a powerful tool that can greatly improve the efficiency and precision of your plastic machining operations. Whether you are a professional manufacturer or a DIY enthusiast, a 3-axis CNC router is an essential tool for achieving high-quality results.

A few examples of products that can be created using a CNC router for plastics:

Signs and displays: Custom signs and displays made out of plastic materials such as acrylic or polycarbonate are popular for their weather resistant properties. These can be used for indoor or outdoor signage, trade show displays, and point-of-purchase displays.

Prototyping: CNC routers are often used to create prototypes of plastic parts and products. This allows designers and engineers to test the form, fit, and function of a product before committing to a full production run. Plastic is a great material for this as it tends to be stable and true to size.

Machine guards and enclosures: CNC routers can be used to create custom machine guards and enclosures out of plastic materials. These can be used to protect workers from moving parts, as well as to enclose and contain machinery for safety and noise reduction.

Medical and dental products: CNC routers are frequently used to create custom medical and dental products such as surgical instruments, dental implants, and prosthetics. The high level of precision and repeatability offered by CNC routers makes them well-suited for these applications.

Consumer products: CNC routers can be used to create a wide range of consumer products, including phone cases, kitchen utensils, and toys.

These are just a few examples of the many products that can be created using a CNC router for plastics. The versatility and precision of CNC routers make them an essential tool for a wide range of industries and applications

A O flute bit is commonly used for routing plastics such as –