Plywood, Router Bits

Utilizing 1/4 Compression Router Bit in 3/4 Plywood on a CNC Router

Selecting the right tool for the job is crucial for achieving a high-quality finish. One tool that can be particularly useful in certain situations is a 1/4″ compression bit. These bits are specifically designed for cutting through thicker materials, such as 3/4″ plywood, with minimal effort and maximum precision. The unique shape of the compression bit is pivotal to materials with a tendency to tear such as plywood.

The heat treatment process gives the bit a hardened cutting edge that can withstand the high forces involved in cutting through thick wood without dulling or breaking. This allows for smoother, more efficient cuts and helps to extend the life of the bit. The chemical property applies to the bits does not transfer to material and helps dissipate heat during the cut process and extend tool life.

The smaller diameter of the 1/4″ allows for greater precision and control, especially when working with intricate designs or tight tolerances. This is especially evident when using this bit with a vacuum hold down method on small parts. It also generates less heat and produces fewer chips, which can help to reduce the risk of burning or damaging the material.

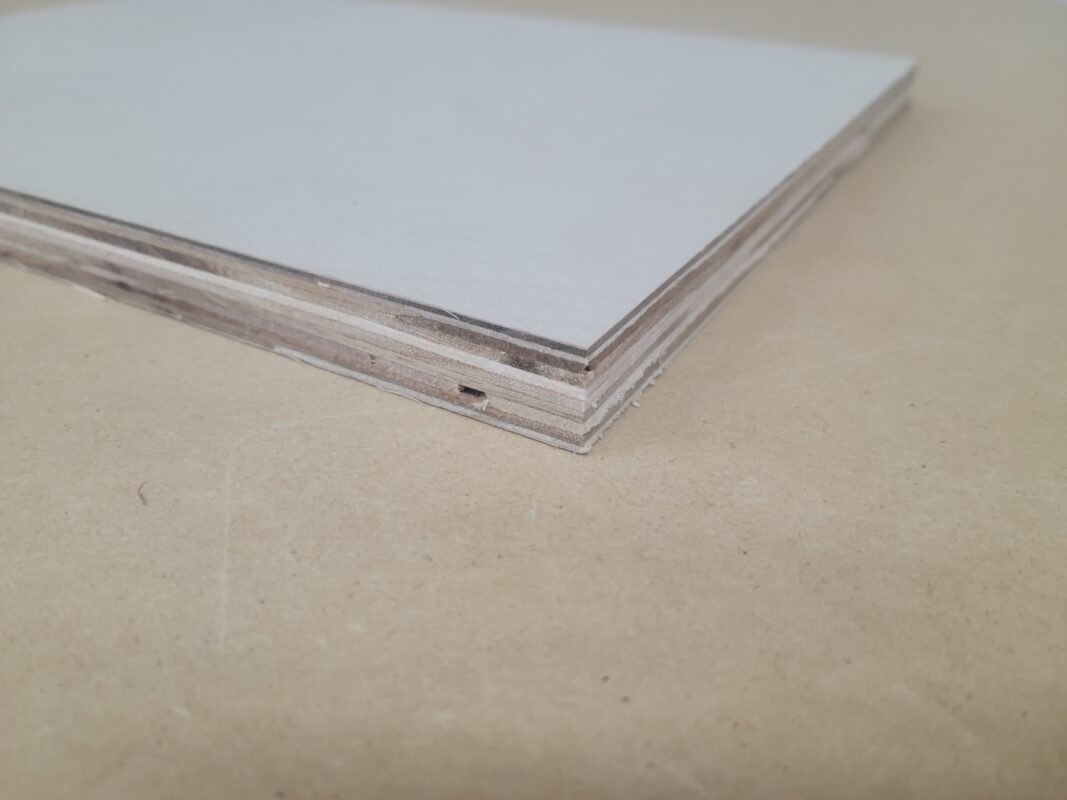

One benefit of the shape of a compression router bit is that it allows for a more efficient cutting action. The upcut and downcut flutes on the bit work together to compress the material as it is being cut, which helps to reduce the amount of chips and debris produced during the cutting process. This can lead to a cleaner and smoother finish, as well as a longer lifespan for the bit.

The 1/4 compression bit is one to certainly have in your arsenal of tooling. It is the best tool for anything plywood related but can also be utilized in MDF and hardwoods. The key thing to keep in mind on the compression bit is the height of the upcut and downcut edges in respect to your material.

Buy your industrial heat coated 1/4 compression bits here: