Uncategorized

The Evolution of Industrial CNC Routers: A Look at the Past, Present, and Future

CNC routers have transformed the manufacturing landscape in countless industries, enabling unprecedented levels of precision, efficiency, and productivity. Over the years, industrial CNC routers have evolved, incorporating advanced technologies and capabilities that have pushed the boundaries of what is possible in terms of design and production. We will take a journey through the evolution of industrial CNC routers, exploring their origins, the milestones in their development, and their potential future trajectory. Innovation is always occurring in this space and the future looks extremely promising as we all work to battle a potential manufacturing labor shortage.

I. The Origins of CNC Routers

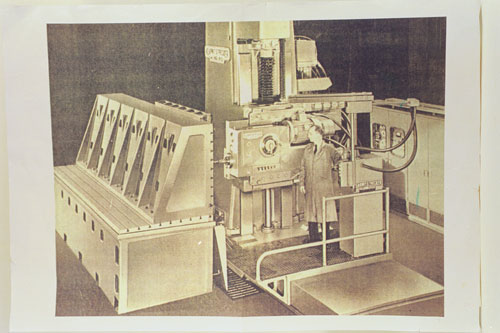

The beginning of CNC technology can be traced back to the 1940s and 1950s when the first numerical control (NC) machines were developed. These early machines relied on punch cards to dictate machine movements, allowing for limited control and automation of machining processes. John T. Parsons, an American engineer, is often credited with the invention of NC technology, and his work laid the groundwork for the development of CNC. John T. Parsons originally worked on this innovation with Frank L. Stulen around the implementation of an advanced process to create helicopter blades.

In the 1960s NC machines evolved into CNC machines. The introduction of computers enabled more complex and precise control over machine movements, paving the way for the first CNC routers. Initially, CNC routers were primarily used in the aerospace and defense industries, where the high levels of precision and automation they offered were critical. This coupled with the reliability and relatively limited downtime helped increase profits.

II. The Growth and Expansion of CNC Router Applications

Over the following decades, as computer technology advanced and became more affordable, CNC routers became more accessible to various industries. By the 1980s and 1990s, CNC routers began to gain widespread adoption in industries such as woodworking, metalworking, and plastics manufacturing. The versatility, precision, and efficiency offered by these machines revolutionized production processes in these sectors.

This revolution in efficiency was also due in part to a parallel innovation in software-

The advent of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software, which allowed for the seamless integration of design and production processes.

Improvements in CNC router construction, including the development of more robust and accurate motion control systems.

Advances in cutting tool technology, such as the introduction of carbide and diamond tooling, which enabled CNC routers to cut a wider range of materials with greater precision and speed.

III. The Present State of Industrial CNC Routers

Today, industrial CNC routers are more advanced and versatile than ever before. Some of the key features and capabilities of modern industrial CNC routers include:

Multi-axis control: While early CNC routers were limited to 2 or 3 axes of motion, modern machines can have up to 5 or more axes. This allows for more complex and intricate cutting and machining operations. This paired with software that does much of the “heavy lifting” for the user allows for an inexperienced operator to still create accurate parts.

Advanced software: The latest CAD/CAM software packages offer powerful design and programming capabilities, including the ability to simulate machining operations before they are executed, reducing errors and waste.

High-speed machining: Modern CNC routers can achieve extremely high cutting speeds, significantly reducing production times and improving efficiency. This is in large part due to advanced algorithms available in industrial CNC controllers commonly referred to as “look ahead”.

Automatic tool changers: These systems enable CNC routers to automatically switch between multiple cutting tools during operation, reducing downtime and enhancing productivity.

Integration with Industry 4.0 technologies: Industrial CNC routers can now be connected to the Internet of Things (IoT), enabling remote monitoring, predictive maintenance, and real-time data analysis.

IV. The Future of Industrial CNC Routers (continued)

As technology continues to advance, we can expect further developments in the capabilities and applications of industrial CNC routes in the manufacturing process. To name a few-

Greater adoption of artificial intelligence (AI) and machine learning in CNC routing processes, allowing for even more efficient and precise machining operations. These technologies can enable CNC routers to adapt and optimize their operations in real-time, reducing errors and waste, and increasing productivity. Increased use of advanced materials, such as composites and nanomaterials, which will require CNC routers to adapt to new cutting techniques and tooling in order to effectively process these materials. We can increase tool life by monitoring router bit temperature and dynamically adjusting RPM to keep the bit in the “sweet spot” and avoid excess heat.

Development of more energy-efficient CNC routers, in line with global trends towards sustainable manufacturing and reduced environmental impact. This could involve the use of alternative energy sources or the development of more energy-efficient motors and drives.

Integration of additive manufacturing (3D printing) technologies with CNC routers, enabling hybrid manufacturing processes that combine the benefits of both subtractive and additive methods. This could lead to greater flexibility and efficiency in the production of complex parts and components. The goal in reaching a more neutral carbon footprint across the manufacturing process can be achieved with modern CNC technology.

The IOT movement and 4.0 technologies in CNC routing enable even greater levels of automation, connectivity, and data-driven decision-making. This could lead to the development of “smart factories” where CNC routers and other manufacturing equipment are fully integrated and communicate with one another to optimize production processes. Imagine a factory that is able to shift production due to a down machine and leverage operating machines to seemingly not skip a beat and avoid downtime.