Uncategorized

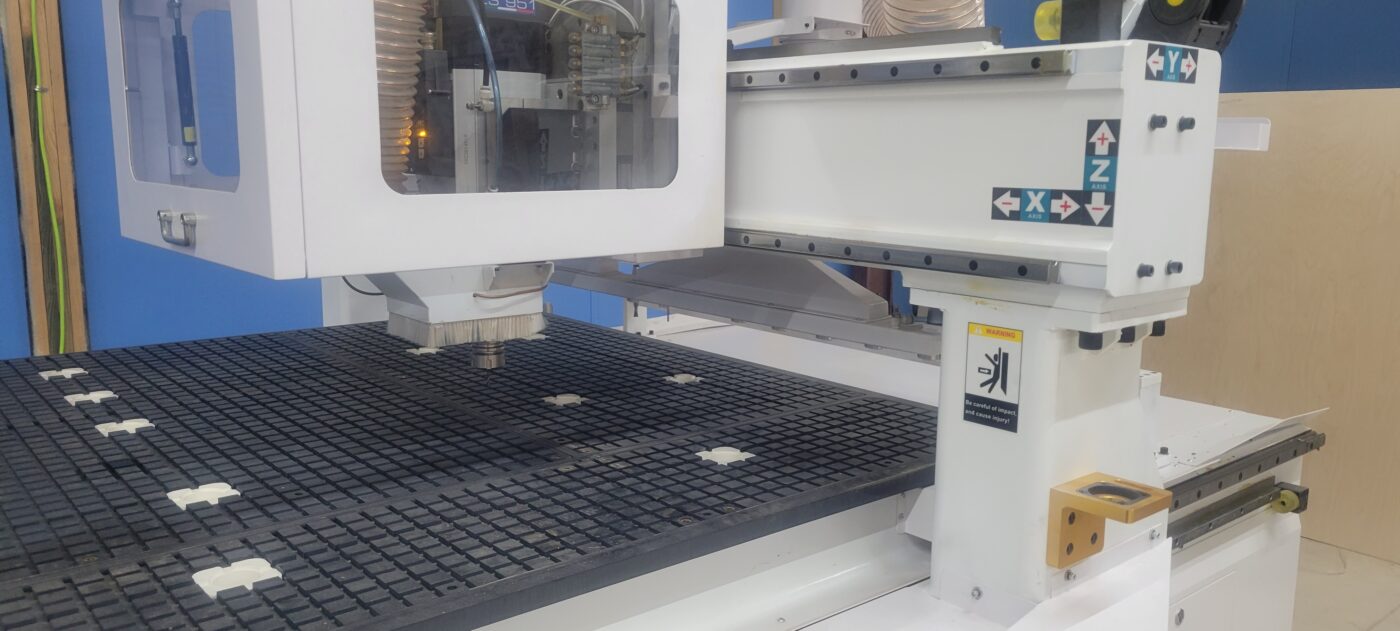

Buying an Industrial 3 Axis CNC Router

Buying an industrial CNC router has many benefits-

Increased accuracy and precision- Industrial CNC routers are designed to be highly accurate and precise, which can be especially important for certain applications, such as prototyping or manufacturing. Often you find the most advanced motors and positioning systems on the industrial machines. This translates into the machine being more accurate longer.

Enhanced productivity- Industrial CNC routers are typically faster and more efficient than smaller, hobby-grade routers, which can help increase productivity and reduce turnaround times. Our 5×10 CNC router moves at speeds in excess of 2,000 IPM rapid and is capable of over 1,000 IPM while cutting. The added weight of 5,00lbs means you can cut thick materials aggressively without the concern of machine chatter translating into your parts.

Greater versatility- Industrial CNC routers often have a larger work envelope and are capable of handling a wider range of materials, which can make them more versatile and suitable for a wider range of applications. Adding a vacuum pump or pop up pins further escalates this production edge.

Improved reliability- Industrial CNC routers are designed to be more durable and reliable, which can be especially important for businesses that rely on their CNC router for production.

Greater scalability- Industrial CNC routers are typically designed to handle higher workloads and can often be easily upgraded or expanded upon as a business grows, which can be especially important for businesses looking to scale up their production.

In addition to being important for producing high-quality parts and components, accuracy and precision can also be important for reducing waste and rework, as it can help to minimize the need for adjustments or corrections. This can help to save time and money, as well as improve efficiency and productivity.

We offer industrial CNC routers built for the most demanding applications and supported from our headquarters in Colorado Springs, CO USA.