Router Bits, Signage, Toolpaths

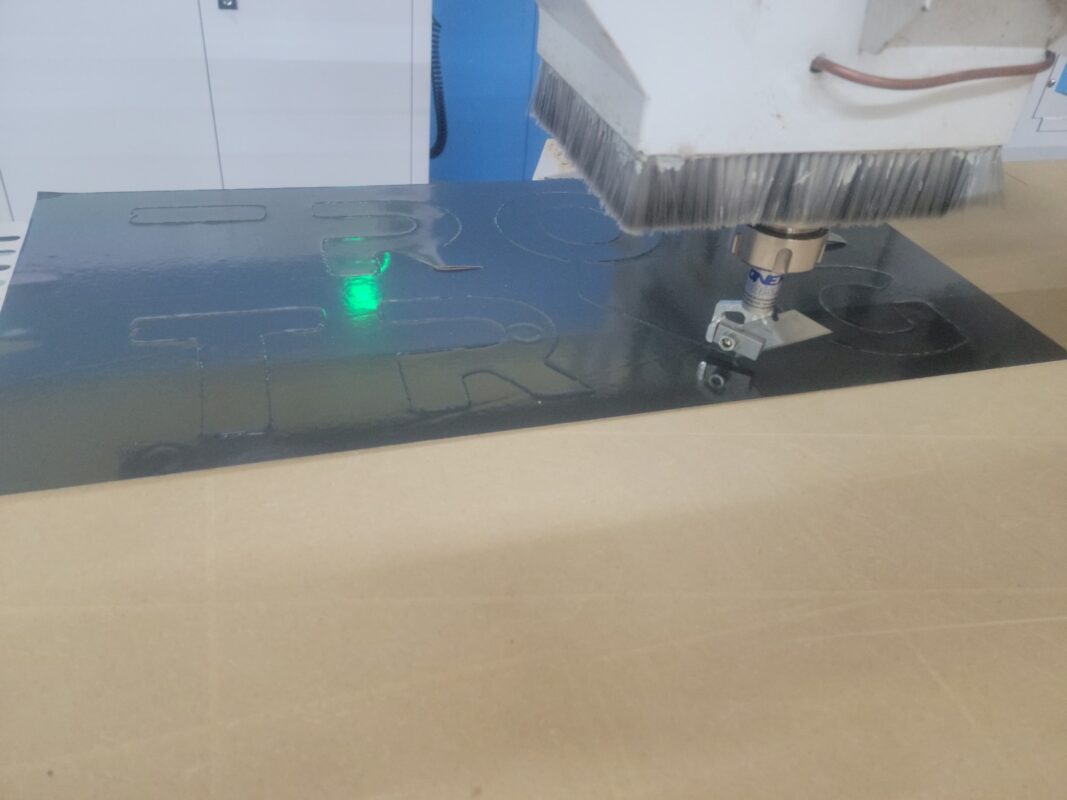

Using a dragknife on a CNC Router

A CNC router can be used for a much wider variety of purposes than may seem evident. One of the more unique tools is that of a dragknife. This tool essentially sits in the toolholder and collet and does not “spin”. Instead it rides on pivoting 360 degree ball bearings and the machine essentially “drags” it across the material, slicing along the way.

A dragknife on a CNC router is a common method for cutting a wide range of materials, including paper, cardstock, vinyl, foam, and more. When you get into thicker materials of paper, cardstock, vinyl or foam, the need of a tangential oscillating knife will start to outweigh the benefits of the dragknife.

There are several benefits in a CNC router. application. First, it allows for the precise and accurate cutting of materials with a high level of detail and complexity. The CNC router can be programmed to follow complex cutting paths and shapes, allowing for the creation of intricate designs and patterns.

Using a dragknife on a CNC router can be an efficient and cost-effective way to cut material that is not more than 1/8″ thick. The CNC router can be programmed to perform multiple cuts in a single setup, saving you valuable production time.

VCarve Pro is a common software program used for dragkife operations. It includes a dragknife gadget that simplifies the creation of the toolpaths.

The dragknife gadget in VCarve Pro is a great gadget that allows users to create dragknife toolpaths. It allows users to specify the size and shape of the blade, as well as the cutting depth and other parameters, although typically this is utilized on thin material such as 1/8″ cardboard or vinyl.

We recommend DonekTools for your dragknife needs.