Pioneer CNC Router: Advanced Production Technology

Take Your Production to the Next Level

Built for professional shops demanding maximum efficiency, precision, and automation

Advanced Production Technology with Superior Performance

4'×8' Model

Perfect for high-volume cabinet shops and production facilities

- ✓ 4'×8' working area

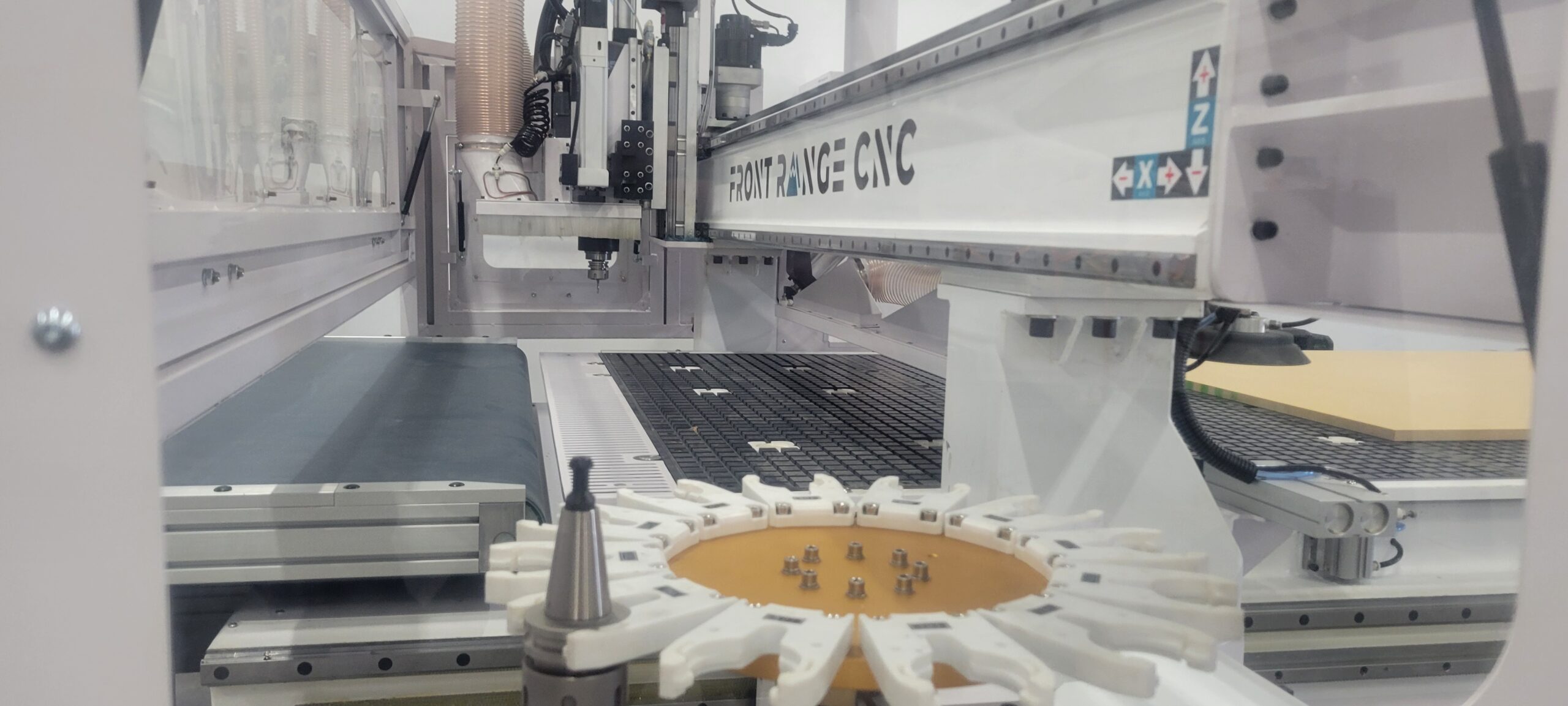

- ✓ Rotary carousel tool changer

- ✓ Automated dust sweep arm

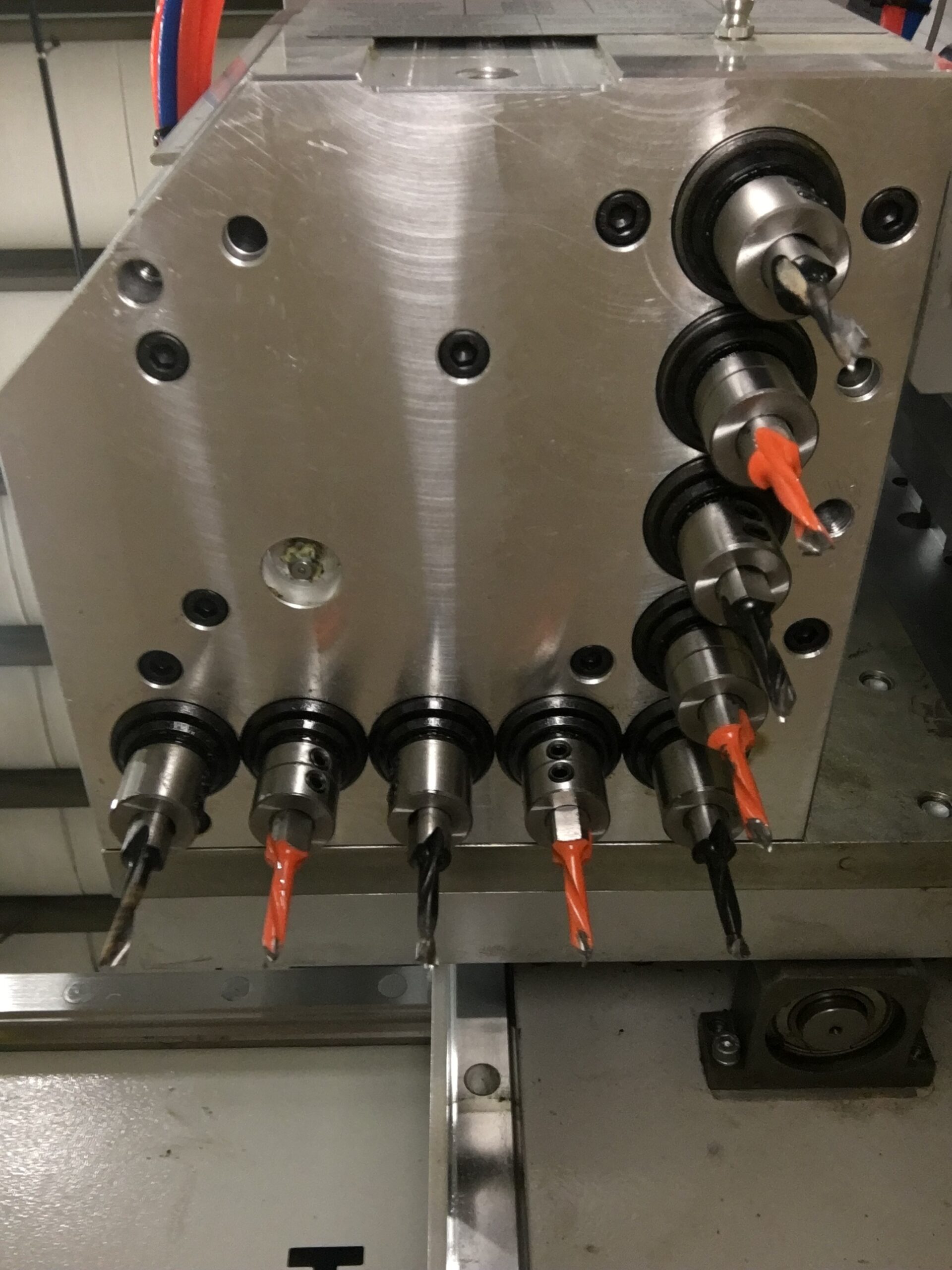

- ✓ 9-position drill bank (Added Feature)

- ✓ Expandable for auto-loading"

- ✓ Laser-calibrated to .001"

5'×10' Model

Ideal for larger material processing with maximum efficiency

- ✓ Extended 5'×10' working area

- ✓ Rotary carousel tool changer

- ✓ Automated dust sweep arm

- ✓ 9-position drill bank (Added Feature)

- ✓ Expandable for auto-loading

- ✓ Laser-calibrated to .001"

5'×12' Model

Extra-long option for specialized material requirements

- ✓ Extended 5'×12' working area

- ✓ Rotary carousel tool changer

- ✓ Automated dust sweep arm

- ✓ 9-position drill bank (Added Feature)

- ✓ Expandable for auto-loading

- ✓ Laser-calibrated to .001"

7'×10' Model

Maximum workspace for large panel processing and nesting. Ideal for SALT panels.

- ✓ Large 7'×10' working area

- ✓ Rotary carousel tool changer

- ✓ Automated dust sweep arm

- ✓ 9-position drill bank (Added Feature)

- ✓ Expandable for auto-loading

- ✓ Laser-calibrated to .001"

Advanced Production-Enhancing Features

Rotary Carousel Tool Changer

The advanced rotary carousel tool changer allows seamless transitions between operations without manual intervention, drastically reducing downtime and increasing overall productivity.

9-Position Drill Bank Plate

Add a 9-position drill bank at the time of purchase or as a future upgrade, allowing simultaneous drilling operations that dramatically reduce cycle times for cabinet manufacturing and other applications.

Automated Dust Sweep Arm

The Dust Sweep Arm system automatically removes dust and debris directly from the cutting area, ensuring consistent precision without manual cleaning interventions and dramatically improving air quality in your production environment.

Laser Calibration to .001"

Every Pioneer CNC is laser calibrated to a precision of .001", ensuring unparalleled accuracy and consistency in every cut. This level of precision delivers superior fit and finish across all your production runs.

Automated Loading/Unloading Ready

Designed with future expansion in mind, the Pioneer Series can be configured for fully automated material loading and unloading, making it the perfect foundation for shops moving toward lights-out manufacturing.

Electronic Vacuum Zones

The Pioneer's electronic vacuum zones open and close at the push of a button. This means less wear on your operator and faster unloading of sheets.

See the Pioneer CNC Router in Action

Precision movements and superior finish quality

Advanced dust sweep technology in action

Optimal for high-volume cabinet production

See the precision, efficiency, and versatility of the Pioneer CNC Router across various applications

Customer Testimonials

"The Pioneer Series transformed our production capabilities. The combination of the rotary tool changer and drill bank has cut our cabinet production time by over 50%, and the automated dust sweep has drastically improved our shop environment."— James Anderson, Premier Cabinetry

"After comparing several industrial CNCs, we chose the Pioneer for its combination of advanced features and expandability. The ability to add automated loading/unloading in the future means our investment is secured as we grow."— Elizabeth Chen, Modern Millworks

The Pioneer Advantage

Rotary carousel tool changer for maximum efficiency

Precision-engineered for superior production

9-position drill bank for rapid hole processing

Industry-Leading Hardware & Construction

Superior frame stability for vibration-free operation

The Pioneer's fully precision-milled steel frame, finished on an aerospace mill, represents the pinnacle of stability and durability in CNC machining. This level of construction quality provides:

- Unmatched Precision and Stability - The frame is manufactured to the highest standards of accuracy for consistent, high-quality cuts

- Enhanced Vibration Dampening - The substantial mass absorbs vibrations, ensuring smoother operation and finer, more precise cuts

- Superior Quality in Machining Complex Materials - Handles challenging materials like metals or dense hardwoods without compromising accuracy

- Reduced Maintenance and Downtime - Less wear and tear means lower operational costs and minimized downtime

Complete Operating Software

-

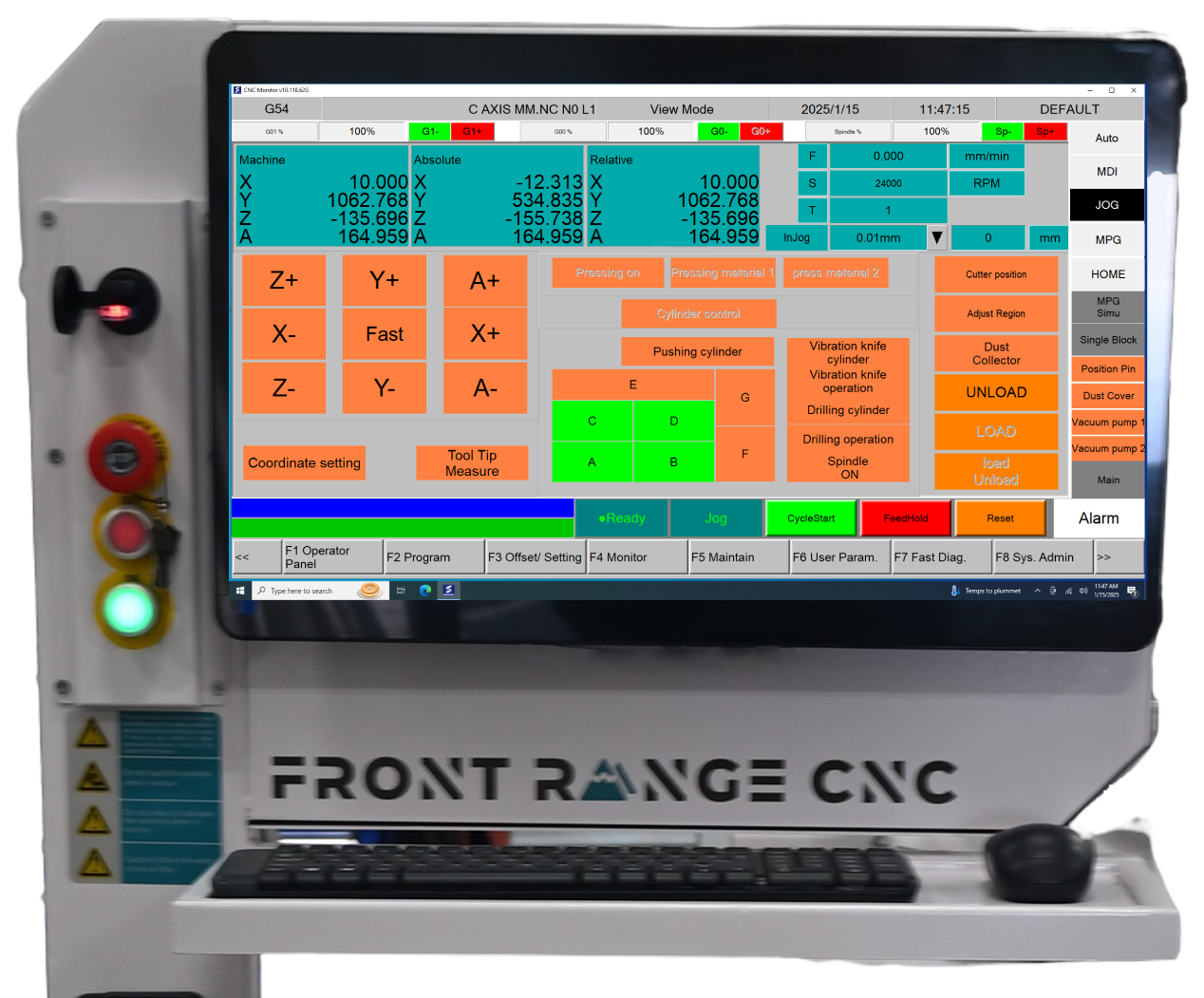

Syntec Controller

Industrial-grade control system with intuitive interface for precise, reliable operation

-

CAM Software Compatibility

Works seamlessly with VCarve Pro, Fusion 360, Mozaik, and all industry-standard CAM software

-

Simple to Use

Easy to use operator interface means less time learning and more time producing

-

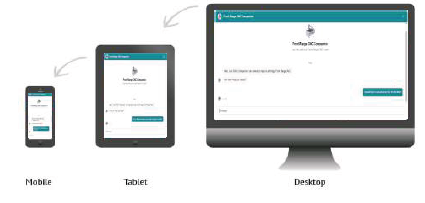

Exclusive CNC Companion

AI-powered 24/7 technical support and optimization assistance to maximize your productivity

Flexible Software Compatability

Easy to Use

AI-powered assistance

Optimal for High-Volume Cabinet Production

The Pioneer Series is optimally designed for high-volume cabinetry production, offering unparalleled precision and efficiency in this specialized field.

Cabinet Manufacturing Benefits:

- 9-Position Drill Bank - Dramatically accelerates cabinet box construction with simultaneous drilling

- Rotary Tool Changer - Seamlessly transitions between operations without manual intervention

- Automated Dust Sweep - Maintains clean cutting surfaces for superior edge quality

- Electronic Vacuum Valves - Ensures precise material hold-down for consistent cuts

Production Advantages:

- Efficiency - Reduce cabinet production time by up to 50%

- Precision - Laser calibrated to .001" for perfect fits every time

- Growth Ready - Expandable for automated loading/unloading

- Versatility - Process a wide range of materials from hardwoods to engineered panels

Technical Specifications

| Feature | 4'×8' Model | 5'×10' Model | 5'×12' Model | 7'×10' Model |

|---|---|---|---|---|

| Z-Axis Travel | 7" (189mm) | 7" (189mm) | 7" (189mm) | 7" (189mm) |

| Z-Axis Clearance | 10" (254mm) | 10" (254mm) | 10" (254mm) | 10" (254mm) |

| Frame Construction | Precision Machined Steel, laser calibrated | Precision Machined Steel, laser calibrated | Precision Machined Steel, laser calibrated | Precision Machined Steel, laser calibrated |

| Tool Change System | Rotary carousel | Rotary carousel | Rotary carousel | Rotary carousel |

| Motors | Industrial servo on all axes, dual motors on Y-axis | Industrial servo on all axes, dual motors on Y-axis | Industrial servo on all axes, dual motors on Y-axis | Industrial servo on all axes, dual motors on Y-axis |

| Control System | Syntec with 21" touchscreen | Syntec with 21" touchscreen | Syntec with 21" touchscreen | Syntec with 21" touchscreen |

| Maximum Speed | 2,500 inches per minute | 2,500 inches per minute | 2,500 inches per minute | 2,500 inches per minute |

| Repeatability | ±0.001" (0.025mm) | ±0.001" (0.025mm) | ±0.001" (0.025mm) | ±0.001" (0.025mm) |

| Spindle | 10HP with automatic tool change | 10HP with automatic tool change | 10HP with automatic tool change | 10HP with automatic tool change |

| Dust Management | Automated dust sweep arm and hood | Automated dust sweep arm and hood | Automated dust sweep arm and hood | Automated dust sweep arm and hood |

| Drill Bank | 9-position ready (optional) | 9-position ready (optional) | 9-position ready (optional) | 9-position ready (optional) |

| Vacuum System | Electronic vacuum valves 4 zone | Electronic vacuum valves 6 zone | Electronic vacuum valves 7 zone | Electronic vacuum valves |

| Material Alignment | Pop-up pin system | Pop-up pin system | Pop-up pin system | Pop-up pin system |

| Power Requirements | Three phase 208-230V | Three phase 208-230V | Three phase 208-230V | Three phase 208-230V |

| Warranty | 1-year parts, lifetime support | 1-year parts, lifetime support | 1-year parts, lifetime support | 1-year parts, lifetime support |

| Working Area | 49" × 97" (1244mm × 2463mm) | 61" × 121" (1549mm × 3073mm) | 61" × 145" (1549mm × 3683mm) | 85" × 121" (2159mm × 3073mm) |

| Well Equipped Price | $65,722 | $67,646 | $75,727 | $77,651 |

Available Accessories & Add-ons

Enhance your Pioneer CNC with these compatible accessories to maximize performance and efficiency.

Altura Precision Vacuum Pump

Our oil-less, low-maintenance vacuum pump provides superior workpiece holding power while operating quietly at just 68dB. Perfectly sized for your Foundation CNC with quick-connect fittings for easy setup.

- Powerful 8.7 HP regenerative vacuum system

- Oil-free operation (no maintenance or oil changes)

- Precise hole spacing for hardware installation

- Can be added initially or as a future upgrade

Rotary Screw Air Compressors

Paired perfectly with your Foundation CNC for automatic tool changes and dust collection systems. Our industrial-grade compressors deliver reliable performance for continuous operation.

- Screw style for noise reduction

- 10-20HP Available

- Integrated air dryer and tank

- Perfect for high-volume production environments

Three-Phase Power

All Pioneer CNC machines are designed for Three Phase 208-230V power. Our team can help you determine the best power solution for your shop setup if you don't currently have three-phase power available.

Get Your Custom Quote Today

Starting at $59,222 for the 4'×8' model and $61,146 for the 5'×10' model, our team will work with you to configure the perfect Foundation CNC solution for your specific production needs and budget.

Tailored to your specific production requirements

Flexible payment plans to fit your budget

Expert assistance for the life of your machine

Or call us directly: (800) 627-0892

Frequently Asked Questions

Ready to Elevate Your Production Capabilities?

Take the next step toward advanced manufacturing efficiency with Front Range CNC's Pioneer Series, starting at $65,722 with financing options as low as $1,094/month.