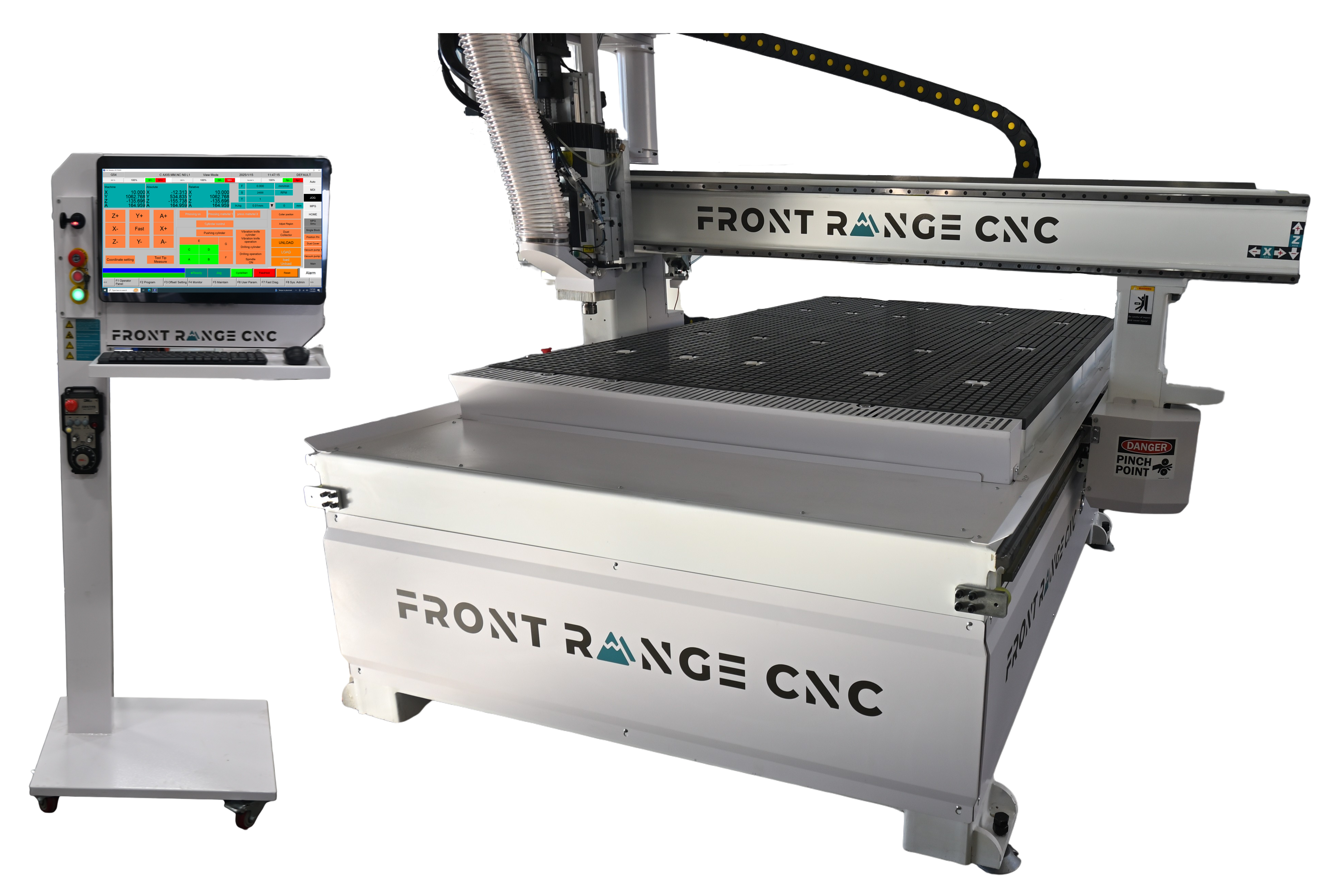

Foundation CNC Router: Industrial-Grade Power & Precision

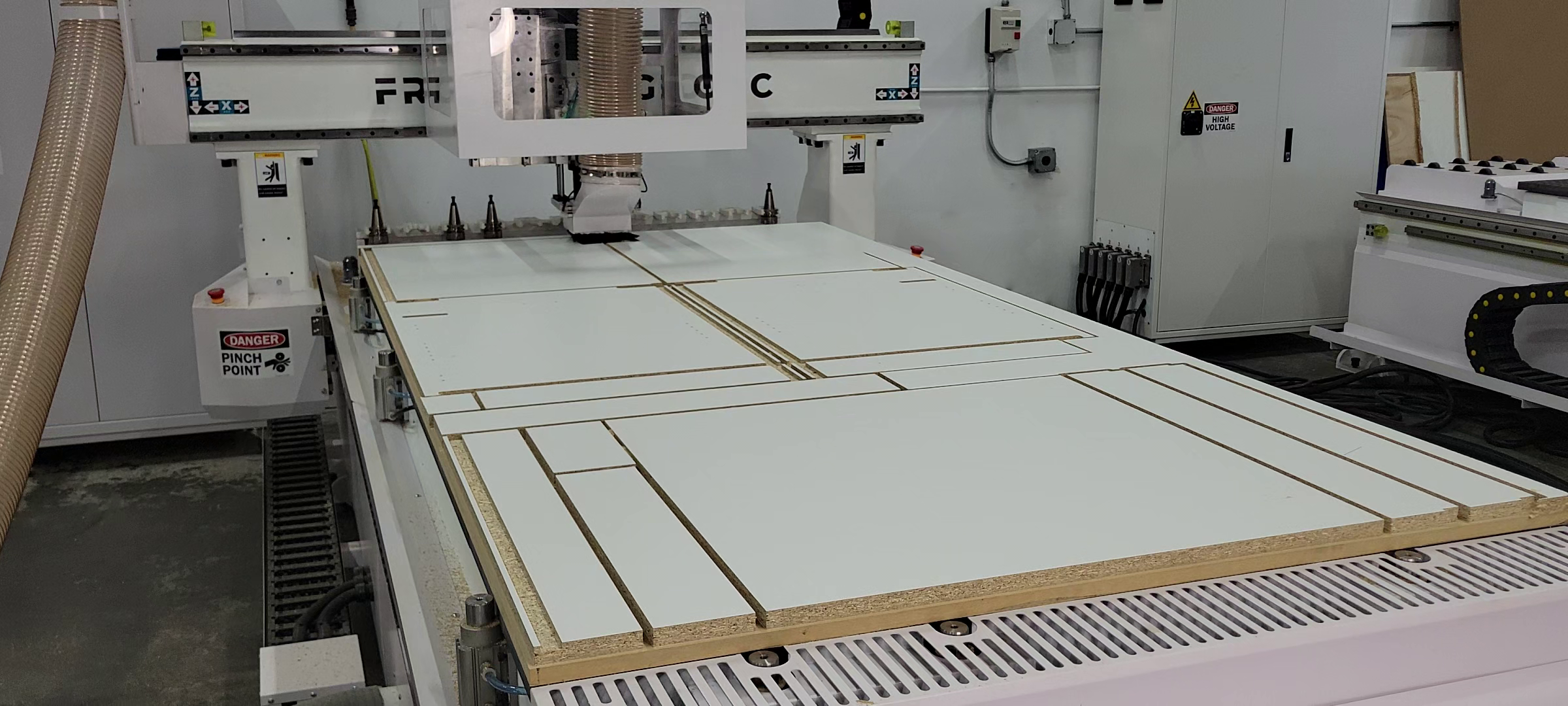

Professional-Grade CNC for Demanding Applications

Built to outperform in woodworking, plastics, and aluminum applications

Professional-Grade Performance At Competitive Pricing

4'×8' Standard Model

Perfect for cabinet shops, sign makers, and furniture manufacturers

- ✓ Standard 4'×8' working area

- ✓ 10HP auto tool change spindle

- ✓ 16" Z-axis travel

- ✓ 12" Z-axis clearance

- ✓ 5,000lb steel frame

5'×10' Standard Model

Ideal for larger material needs such as Baltic Birch or specialized 5'x5' sheets.

- ✓ Extended 5'×10' working area

- ✓ 10HP auto tool change spindle

- ✓ 16" Z-axis travel

- ✓ 12" Z-axis clearance

- ✓ 5,500lb steel frame

Experience Industrial-Grade Performance

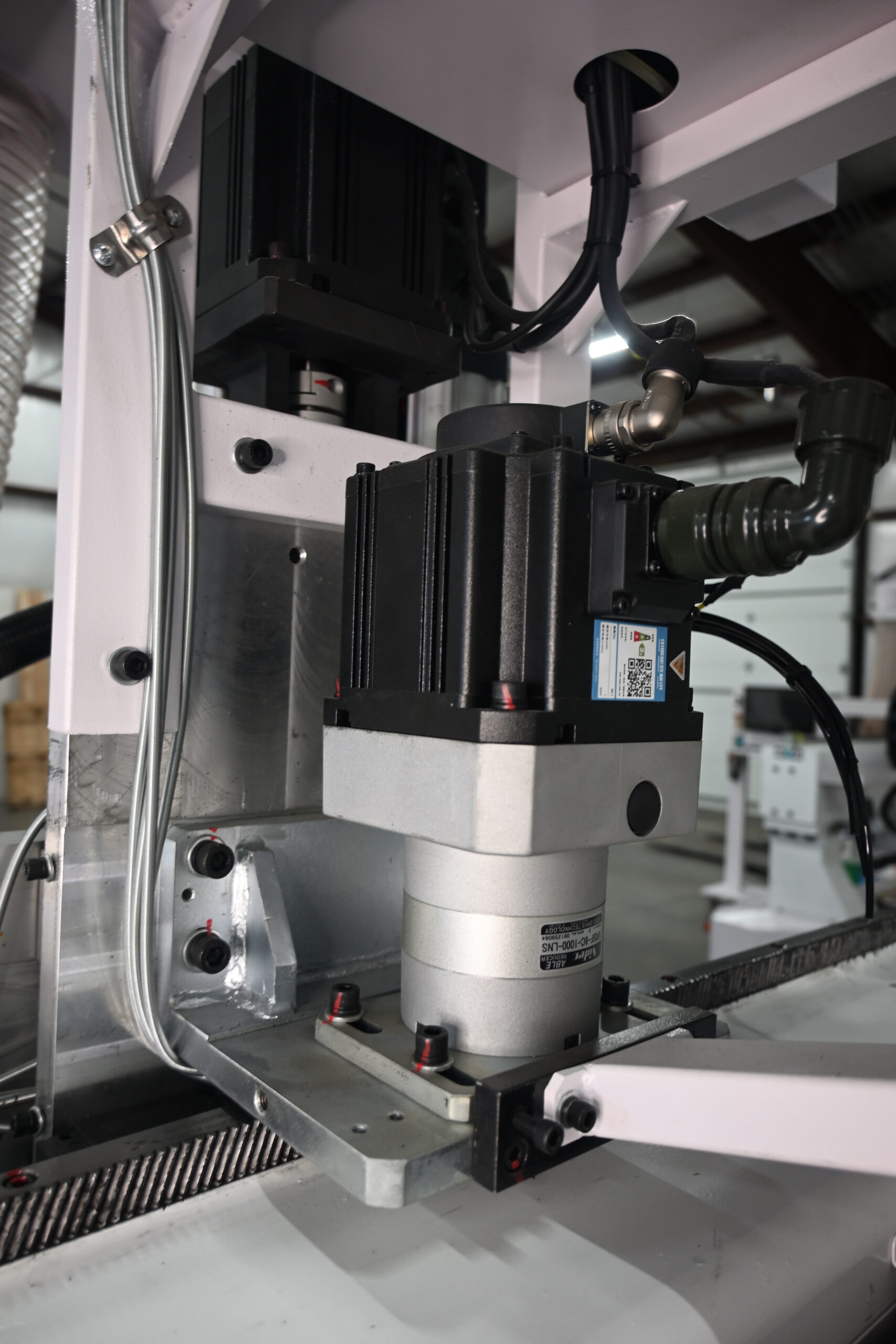

1,000-Watt Servo Motors

Direct-drive planetary gearboxes with 1,000-watt oversized servo motors deliver exceptional power, precision, and efficiency with minimal backlash.

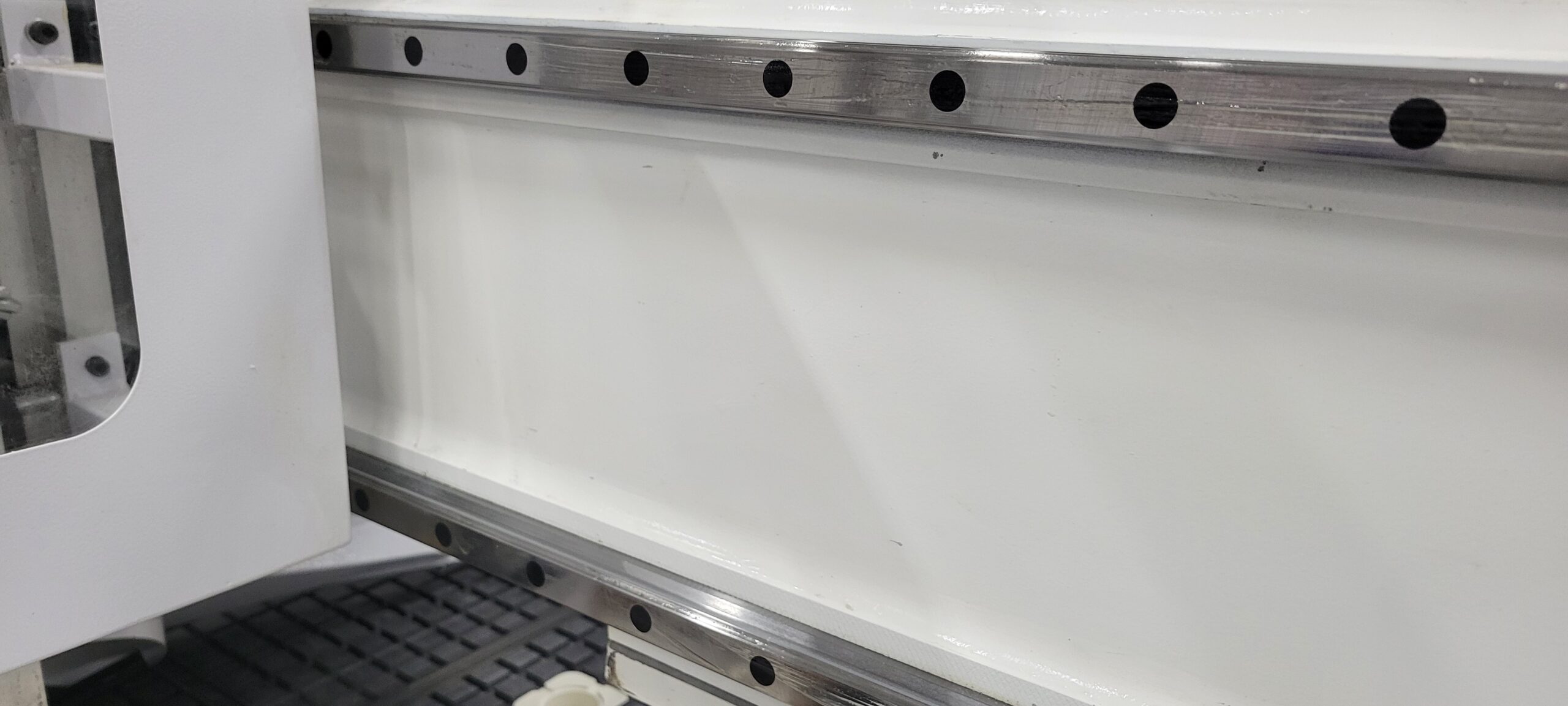

Fully Steel-Welded Frame

Precision-milled one-piece steel frame finished on an aerospace mill and laser calibrated ensures unmatched stability, vibration dampening, and long-term durability.

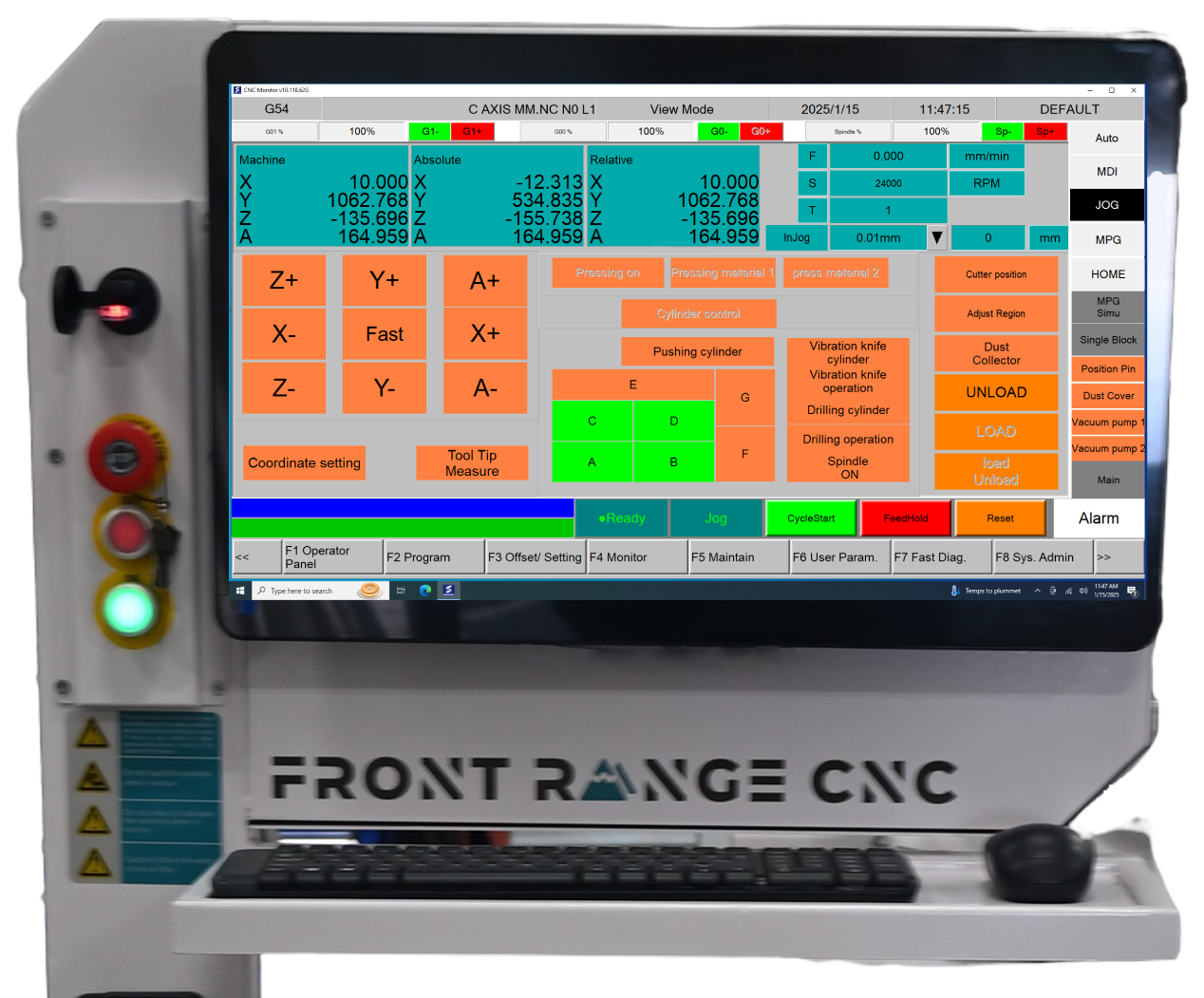

Powerful, Easy to Use Control System

Our hybrid control system combines industrial-grade Syntec CNC with a user-friendly PC interface, featuring a large 21-inch touchscreen. This unique approach delivers the precision and reliability of professional CNC technology with intuitive operation that requires minimal training—allowing anyone from seasoned machinists to new operators to efficiently run complex projects with confidence.

Self-Installation Savings

Comprehensive video guides and step-by-step instructions allow for easy self-installation, saving thousands in technician costs while maintaining complete setup support.

AI-Powered CNC Companion

Our exclusive CNC Companion provides intelligent support with AI-driven troubleshooting, real-time optimization suggestions, and predictive maintenance alerts to maximize your productivity and minimize downtime.

Production-Ready Tooling Included

Hit the ground running with our included professional tooling package featuring ISO30 tool holders, premium carbide cutting bits for various applications, collets, wrenches, and setup tools. Start cutting on day one without the delay and expense of sourcing additional components.

See the Foundation CNC Router in Action

Watch our Foundation CNC router cut complex cabinet components with perfect precision

The Foundation Advantage

Full steel welded frame

Automatic lubrication for low maintenance

Intuitive 21" control interface

Industry-Leading Hardware

Premium 25mm linear profile rails for precision movement

Dual 1,000-watt servo motors on Y-axis for stability

Complete Operating Software

-

Syntec Controller

Industrial-grade control system with intuitive interface for precise, reliable operation

-

CAM Software Compatibility

Works seamlessly with VCarve Pro, Fusion 360, Mozaik, and all industry-standard CAM software

-

Simple to Use

Easy to use operator interface means less time learning and more time producing

-

Exclusive CNC Companion

AI-powered 24/7 technical support and optimization assistance to maximize your productivity

Flexible Software Compatability

Easy to Use

AI-powered assistance

Versatile Applications

Custom Cabinetry

Commercial Signage

Architectural Millwork

Aluminum Fabrication

Technical Specifications

| Feature | 4'×8' Model | 5'×10' Model |

|---|---|---|

| Working Area | 49" × 97" (1244mm × 2463mm) | 61" × 121" (1549mm × 3073mm) |

| Price | $45,343 | $47,045 |

| Z-Axis Travel | 16" (406mm) | 16" (406mm) |

| Z-Axis Clearance | 12" (304mm) | 12" (304mm) |

| Frame Construction | Precision-milled steel, 4,500lbs | Precision-milled steel, 5,200lbs |

| Spindle | 10HP with automatic tool change | 10HP with automatic tool change |

| Motors | 1,000-watt servo on all axes, dual motors on Y-axis | 1,000-watt servo on all axes, dual motors on Y-axis |

| Control System | Syntec with 21" touchscreen | Syntec with 21" touchscreen |

| Maximum Speed | 2,500 inches per minute | 2,500 inches per minute |

| Repeatability | ±0.001" (0.025mm) | ±0.001" (0.025mm) |

| Tool Holders | 12 ISO30 (standard) | 12 ISO30 (standard) |

| Vacuum Zones | 4 Zone Manual Valves | 6 Zone Manual Valves |

| Power Requirements | Three phase or single phase | Three phase or single phase |

| Warranty | 1-year parts, lifetime support | 1-year parts, lifetime support |

Available Accessories & Add-ons

Enhance your Foundation CNC with these compatible accessories to maximize performance and efficiency.

Altura Precision Vacuum Pump

Our oil-less, low-maintenance vacuum pump provides superior workpiece holding power while operating quietly at just 68dB. Perfectly sized for your Foundation CNC with quick-connect fittings for easy setup.

- Powerful 8.7 HP regenerative vacuum system

- Oil-free operation (no maintenance or oil changes)

- Check Valve and digital vacuum gauge

Industrial Air Compressor

Paired perfectly with your Foundation CNC for automatic tool changes and dust collection systems. Our industrial-grade compressors deliver reliable performance for continuous operation.

- 5HP-20HP available

- 80-gallon vertical tank design

- Two-stage pump for efficiency and longevity

Single-Phase Compatibility

All Foundation CNC machines are compatible with Single Phase or Three Phase available in most shops and garages. No need for expensive three-phase power conversion or installation—simply plug into your existing electrical infrastructure and start production.

Get Your Custom Quote Today

Starting at $42,343 for the 4'×8' model and $44,045 for the 5'×10' model, our team will work with you to configure the perfect Foundation CNC solution for your specific production needs and budget.

Tailored to your specific production requirements

Flexible payment plans to fit your budget

Expert assistance for the life of your machine

Or call us directly: (800) 627-0892

Frequently Asked Questions

Ready to Transform Your Production?

Take the next step toward precision manufacturing with Front Range CNC's Foundation router, starting at just $44,843.