Aluminum and Non-Ferrous Routing

The Elite and Pioneer series from Front Range CNC are exceptionally well-suited for aluminum applications, combining advanced technology, robust construction, and customizable features to meet the specific demands of machining this versatile metal.

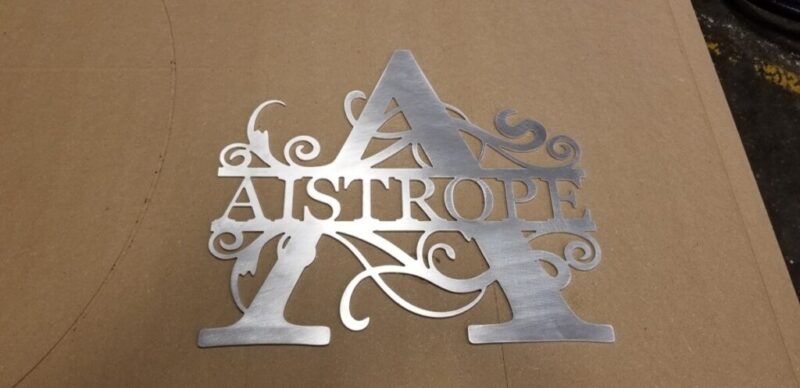

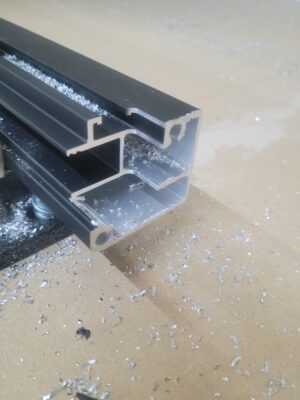

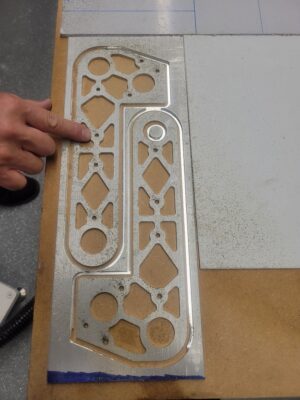

- Precision and Power for Aluminum Machining: Both the Elite and Pioneer series boast the necessary precision and power to handle aluminum, a metal known for its lightweight and strength. The high-quality spindles in these machines provide the accurate and clean cuts required for aluminum, while the robust construction ensures stability during the machining process, which is crucial for achieving precise results in this softer metal.

- Advanced Control Systems for Detailed Work: With sophisticated control systems from Fanuc, Fagor, and Syntec, both series offer precise adjustments and control, vital for the intricate machining often required in aluminum applications. These systems allow for fine-tuning of the machining process, ensuring that even the most complex aluminum parts are crafted with precision.

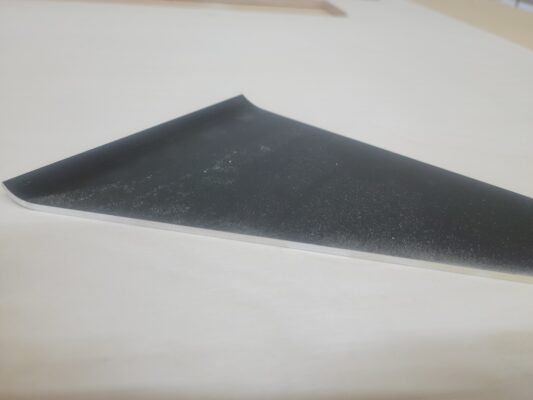

- Customizable Tooling and Speed Settings: Aluminum machining often requires specific tooling and speed adjustments. Both the Elite and Pioneer series offer a range of tooling options and variable speed settings, allowing operators to optimize the machines for different types of aluminum work, from thin sheets to thicker blocks.

- Mist Systems for Enhanced Machining: The ability to add mist systems to both the Elite and Pioneer series is a significant advantage in aluminum machining. The mist system helps in cooling the cutting tools and workpiece, reducing the risk of warping or other heat-related deformations in the aluminum. This cooling feature is particularly beneficial when working with high-speed cuts or prolonged operations.

- Standard Air Blowoff at the Tool: A critical feature in both series is the air blowoff at the tool, a standard inclusion that helps keep the cutting area clean and free from debris. This feature is especially important in aluminum machining, where the accumulation of chips and shavings can affect the quality of the cut and potentially damage the tooling. The air blowoff ensures that the cutting area remains clear, enhancing both the quality of the cut and the longevity of the tools.