5-Axis Moving Table CNC Router

Advanced Multi-Axis Precision & Performance

Engineered for complex machining applications with superior stability and accuracy

Precision and Durability

The Moving Table 5-Axis CNC Machine from Front Range CNC is a cutting-edge solution tailored for industries requiring high precision, scalability, and versatility. With a robust moving table design, this machine supports larger workpieces while maintaining exceptional stability and accuracy, making it ideal for complex prototyping, detailed mold creation, and custom fabrication.

Key advantages include a spacious working area with simultaneous multi-axis movement, enabling the machining of intricate geometries and undercuts with ease. Its heavy-duty steel frame minimizes vibrations for consistent accuracy, while an advanced 5-axis controller ensures seamless operation. This machine excels across diverse applications, from mold manufacturing to furniture production, processing materials such as wood, foam, plastics, aluminum, and brass.

Packed with user-focused features like automatic tool calibration, centralized oiling systems, and spindle chiller, the Moving Table 5-Axis CNC Machine is designed for efficiency and reliability. Whether producing detailed prototypes or high-quality custom parts, it offers unmatched performance and adaptability for modern manufacturing needs.

Advanced 5-Axis Capabilities

Multi-Axis Movement

Simultaneous 5-axis movement allows for complex geometries, undercuts, and intricate details that would be impossible with traditional 3-axis machines. Perfect for advanced mold making and complex component manufacturing.

Moving Table Design

The innovative moving table design provides superior stability during machining operations, allowing for larger workpieces while maintaining precise tolerances throughout the entire cutting process.

Advanced Control System

Equipped with Syntec 5-axis controller 610MA-E5 (with RTCP) or optional Fagor 8065, providing intuitive programming interface with powerful capabilities for complex tool path generation and machine control.

Precision Components

Built with premium components including THK guide rails, Yaskawa servo motors, and APEX planetary reducers for maximum precision, durability, and reliability in demanding production environments.

Industrial-Grade Construction

Features a robust, thick steel tube frame that undergoes vibration stress relief and tempering processes. The full steel welding and internal reinforcement ensures exceptional stability during complex machining operations.

Premium Hiteco Spindle

Equipped with a powerful 15/17kW Hiteco spindle with HSK63F tool holder and 24,000 RPM capability, providing the performance needed for precision machining across a wide range of materials.

See the 5-Axis Moving Table CNC in Detail

Complete 5-Axis CNC system with moving table design

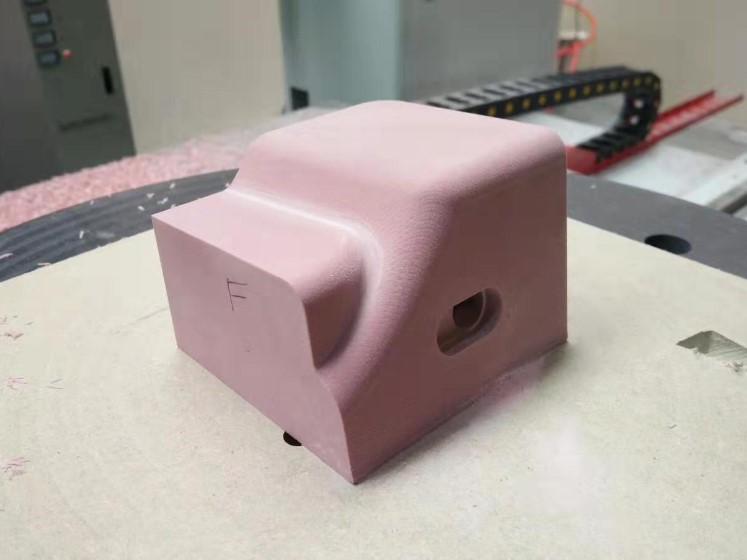

Precision-engineered 5-axis cutting head

Premium Hiteco 15/17kW spindle with 24,000 RPM capability

Optional full enclosure for enhanced safety and dust control

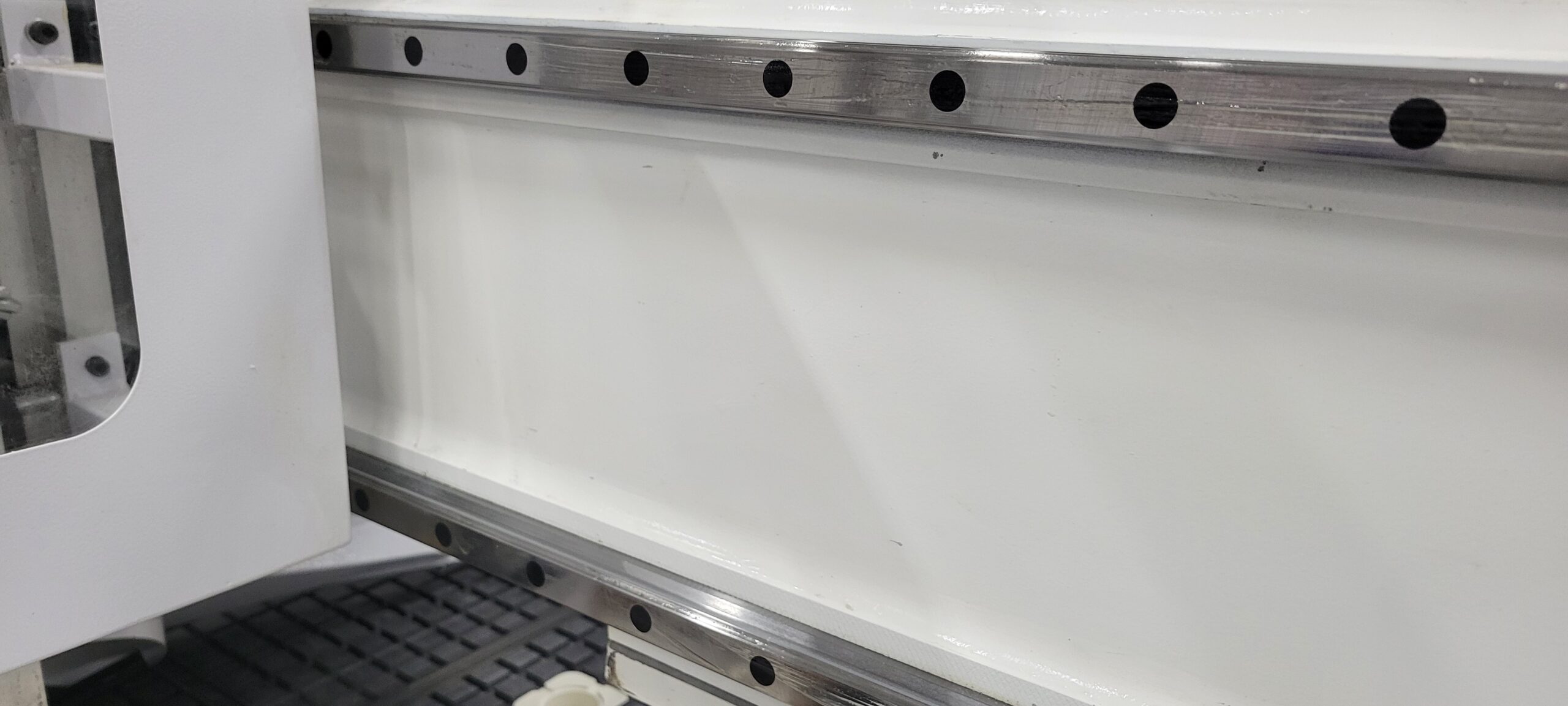

Robust construction for maximum stability during operation

Advanced control system for precise machining operations

Technical Specifications

| Technical Parameter | |||

|---|---|---|---|

| Effective working area | 3-axis stroke | X:157in Y:98in Z:47in | |

| 5-axis working size | X:118in Y:59in Z:31in | ||

| A axis | ±120° | ||

| C axis | ±360° | ||

| Table | Steel plate welded, vacuum+T slot combined | ||

| 5-axis head | Type | L type | |

| Encoder | Included | ||

| Brake | Included | ||

| Spindle | Spindle brand | Hiteco | |

| Spindle power | 15/17kw spindle | ||

| Max rev | 24000 rpm | ||

| Tool holder | HSK63F | ||

| Cooling system | Water cooling system with industrial chiller | ||

| Tool magazine | Carousel type 8pcs | ||

| Control system | Syntec 5-axis controller 610MA-E5 (with RTCP) or Fagor 8065 | ||

| Remote handle | Wireless | ||

| Controller trolley | Yes | ||

| Servo motor | Yaskawa servo motor | ||

| Reducer | APEX planetary reducer | ||

| Control cabinet | Independent control cabinet with forced cooling system | ||

| Guide rail | THK guide rail | ||

| Guide rail protect | Flexible cover on XY, to protect the transmission | ||

| Mainly electric parts | Schneider | ||

| Tool calibration | Renishaw TS27R | ||

| Anti-static | EXAIR Super Ion Air Cannon | ||

| Cable | Igus | ||

| Oiling system | Auto central oiling system | ||

| Working voltage | AC480V 50-60Hz 3Phase | ||

| Package | Iron tray | ||

| Positioning accuracy | ±X:0.005 | ±Y:0.005 | ±Z:0.005 |

| Re-position accuracy | ±X:0.001 | ±Y:0.001 | ±Z:0.001 |

| Application | |||

| Applicable materials | Wood, Foam, Plastic, EPS and light-metallic (Aluminum/brass), etc. | ||

| Applicable industries |

|

||

| Working effect | Engraving, cutting, milling, drilling, trimming, etc. | ||

Ready to Transform Your Manufacturing Capabilities?

Contact us today to discuss how our 5-Axis Moving Table CNC Router can elevate your production to new levels of precision and efficiency.

Request a Custom Quote Contact UsFrequently Asked Questions

Premium Components for Superior Performance

Yaskawa Servo Motors

Premium Japanese servo motors providing exceptional precision, reliability, and longevity for demanding production environments

THK Linear Guide Rails

Industry-leading THK guide rails deliver smooth, precise movement and exceptional durability even under heavy loads

Auto Central Oiling System

Automated lubrication extends component life, reduces maintenance, and ensures consistent performance

Advanced Control System

Syntec 5-Axis Controller

The Syntec 610MA-E5 controller provides powerful 5-axis control with RTCP (Rotating Tool Center Point) functionality, allowing for seamless machining of complex contours. Key features include:

- Intuitive user interface with 21" touchscreen

- Advanced interpolation algorithms for smooth contouring

- Real-time tool path visualization

- High-speed data processing for complex operations

- Compatible with standard G-code programming

- Integrated with wireless remote handle for easy operation

The control system enables operators of varying experience levels to achieve professional results with minimal training, while still providing the advanced capabilities required for complex manufacturing operations.

Additional Premium Features

Renishaw Tool Calibration

Equipped with Renishaw TS27R tool setting probe for automatic tool measurement, providing exceptional accuracy and consistency in machining operations.

Anti-Static System

EXAIR Super Ion Air Cannon eliminates static electricity during machining, improving material handling and ensuring consistent finish quality.

Advanced Cooling System

Integrated water cooling system with industrial chiller maintains optimal spindle temperature for extended life and consistent performance.

Guide Rail Protection

Flexible covers on X and Y axes protect critical guide rails and drive systems from dust and debris, extending component life.

Premium Electronics

Schneider electrical components and Igus premium cables ensure reliable operation and reduced maintenance requirements.

Wireless Remote Control

Included wireless remote handle allows for convenient machine operation and fine adjustment during setup and operation.

Transform Your Manufacturing Capabilities Today

The 5-Axis Moving Table CNC Router represents the pinnacle of precision manufacturing technology, offering unmatched versatility, accuracy, and productivity for demanding applications.